Research on the thermal load calculation and its impact factors for office building [ PDF

全文

(2) Table 3 Comparison of calculation formula. [2], [3]. Cooling load Element. Chinese method. Japanese method. Differenc. External wall. Q=A·K·(tτ —ξ —tn) A:Calculation area,[㎡] K:Heat transfer coefficient,[W/(㎡·℃)] τ :Calculation time,[h] tτ —ξ :Outdoor calculation temperature,[℃] tn:Indoor temperature.[℃]. Q=A·K·ETDj A:Calculation area,[㎡] K:Heat transfer coefficient,[W/(㎡·℃)] ETDj:Equivalent temperature,[℃]. In the meaning of formula tτ —ξ —tn is same as ETDj, but the setting values are different.. Q=A·K·(tn-tw)·a Interior wall,(the formula K:Heat transfer coefficient,[W/(㎡·℃)] to calculate thermal load A:Calculation area,[㎡] for interior wall is same a:Temperature difference correction coefficient,[-] in cooling load and tw:Outdoor temperature,[℃] heating load) tn:Indoor temperature,[℃]. Q=A·K·a·(tn-tw) a:Temperature difference coefficient,[-] K:Heat transfer coefficient,[W/(㎡·℃)] A:Calculation area,[㎡] tw:Outdoor temperature,[℃] tn:Indoor temperature,[℃]. Almost same without to considering about setting values.. Window(Heat transfer by temperature difference). Q=a·K·A·(tτ —tn) tτ :Cooling load temperature of calculation time,[℃] K:Heat transfer coefficient,[W/(㎡·℃)] a:Correction coefficient of window frame,[—] A:Calculation area,[㎡] tn:indoor temperature,[℃]. Q=A·K·(toj—tn) toj:Outdoor temperature for cooling load calculation,[℃] A:Calculation area,[㎡] K:Heat transfer coefficient,[W/(㎡·℃)] tn:indoor temperature,[℃]. tτ and toj are correct outdoor temperature,but the setting values are different.. Window(Solar radiation). Q=A·Xg·Xd·IGC Xg:Correction coefficient of window structure,[—] Xd:Correction coefficient of location,[—] IGC:Solar radiation intensity,[W/㎡] A:Calculation area,[㎡]. Q=IGJ·SC·A IGJ:Solar radiation intensity,[W/㎡] SC:Shading coefficient,[—] A:Calculation area,[㎡]. In Chinese method Xg, Xd is used as a correction coefficient.. Internal heat generation from human body. Q=n·q1·Xτ —T Q=φ ·n·q2 n:Numbers of human,[person] q1:Sensible heat of an adult man per hour,[W] Xτ —T:Sensible heatrelease cooling load coefficient,[—] φ :Clustering coefficient,[—] q2:Latent heat per person,[W/person]. Q=n·(qHSP—qHLP) n:Numbers of human body,[person] qHSP:Sensible heat per person,[W/person] qHLP:Latent heat per person,[W/person]. In Chinese method, the Xτ —T is used as a correction coefficient.. Internal heat generation from lighting. Q=n·N·Xτ —T n:Simultaneous use coefficient,(0.6-0.8),we use 0.7 N:Power density of lighting,[W] Xτ —T:Heat dissipation cooling coefficient,[—]. Q=A·WL A:Calculation area,[㎡] WL:Power density for lighting,[W/㎡]. In Chinese method, the Xτ —T is used as a correction coefficient.. Internal heat generation from equipment. Q=A·qf·Xτ —T A:Calculation area,[㎡] qf:Power density of equipment,[W/㎡] Xτ —T:Heat dissipation cooling coefficient,[—]. Q=φ ·Pf·A φ :Load rate,(φ =0.6),[—] qf:Power density of equipment,[W/㎡] A:Calculation area,[㎡]. In Chinese method, the Xτ —T is used as a correction coefficient.. Air infiltration. Q=0.28·G·(tw—tn) Q=0.28·G·(hw-hn) G:volume of infiltration air,[kg/h] hw:Enthalpy of outdoor,[kJ/kg] hn:Enthalpy of indoor,[kJ/kg] tw:Outdoor temperature,[℃] tn:Indoor temperat,[℃]. Q=QI·A·[0.33(toj-ti)+833(xo-xi)] xo:Outdoor absolute humidity,[g/kg] xi:Indoor absolute humidity,[g/kg] A:Sash area,[㎡] QI:Air infiltration per unit area,[m³/(㎡·h)] toj:Outdoor temperature,[℃] ti:Indoor temperature,[℃]. Almost same without to considering about setting values.. Fresh air. Q=0.33·N·QP·(hoj-hi) Q=0.33·N·QP·(hoj-hi) N:Numbers of human,[person] N:Numbers of human,[person] Almost same without to QP:Volume of fresh air per person,[m³/(h·person)] QP:Volume of fresh air per person,[m³/(h·person)] considering about setting hoj:Enthalpy of outdoor,[kJ/kg] hoj:Enthalpy of outdoor,[kJ/kg] values. hi:Enthalpy of indoor,[kJ/kg] hi:Enthalpy of indoor,[kJ/kg] Heating load. Element. Chinese method. External wall Internal wall Window. Q=A·K·(tn-tw)·a K:Heat transfer coefficient,[W/(㎡·℃)] A:Calculation area,[㎡] a:Temperature difference correction coefficient,[-] tw:Outdoor temperature,[℃] tn:Indoor temperature,[℃]. Air infiltration. Q=0.278·CP·(l·L·n)·ρ W·(tn-tw) CP:Heat capacity,[CP=1.0056kJ/(kg·℃)] ρ W:Air density,[kg/m³] l:Length of gap,[m] L:Air infiltration volume per meter,[m³/m·h] n:Direction coefficient,[-]. Fresh air. Q=Mo·CP·(to-ti) CP:Heat capacity,[CP=1.0056kJ/(kg·℃)] to:Outdoor temperature,[℃] ti:Indoor temperature,[℃] Mo:Volume of fresh air,[kg/s]. Japanese method Q=A·K·(tn-tw)·δ Q=A·K·a·(tn-tw) δ :Direction coefficient,[-] a:Temperature difference coefficient,[-] K:Heat transfer coefficient,[W/(㎡·℃)] A:Calculation area,[㎡] tw:Outdoor temperature,[℃] tn:Indoor temperature,[℃] Q=A·Qi·[0.33·(ti-to)+833·(xi-xo)] Qi:Volume of infiltration air per unit are,[m³/h] A:Calculation area,[㎡] ti:Indoor temperature,[℃] to:Outdoor temperature,[℃] xi:Indoor absolute humidity,[g/kg] xo:Outdoor absolute humidity,[g/kg]. Difference. In Japanese method, δ and r is used as a correction coefficient.. In Japanese method, also consider about humidity.. Q=0.33·N·QP·(hoj-hi) N:Numbers of human,[person] Almost same without to QP:Volume of fresh air per person,[m³/(h·person)] considering about setting hoj:Enthalpy of outdoor,[kJ/kg] values. hi:Enthalpy of indoor,[kJ/kg]. 47-2.

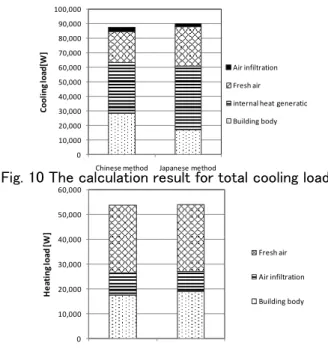

(3) Formulas for calculating every part of thermal loads. In the thermal load calculation for internal heat. are shown as table 3. There was no big difference in the. generation of Chinese method, there were some. essence and object of formula in each method. However,. parameters which called cooling load factors and those. there were still some small differences in detail.. were changing along with time and the details were. thermal load. calculation. using the. local. shown in the Fig. 7.Another reason of cities’ selected is. meteorological condition parameters to get the standard. by the rule of the heating degree day base on 18℃, and. day result.. the result is very close between those two cities.. The thermal calculation result for external was shown. And the heating load calculation results were shown as. as Fig. 3, and the table 4 shows the different equivalent. follows:Fig. 8 shows the result for building body and the. temperatures for Chinese method and Japanese method.. Fig.9 shows that for infiltration and fresh air. The Fig. 10. The Fig. 4 shows the result for windows, and the table 5. and Fig. 11 show the calculation result for total cooling. shows the solar radiation intensity for Chinese method. load and total heating load.. Table 4 Equivalent temperature,[℃]. and Japanese method. The setting parameter for sensible and latent for human body was shown in table 6. Fig. 5. N E S W. and Fig. 6 show the calculation result for internal heat generation infiltration and fresh air respectively. And all. N E S W. the result above was the cooling load result.. Table 5 Solar radiation. Humanof Bodyinternal Lighting Equipment Table 6 Setting heat. N E S W. 12 o'clock Chinese Japanese 134 43 207 43 180 180 134 50 16 o'clock Chinese Japanese 110 38 122 36 114 36 462 609. Human body. Changing. 40,000. Sensible heat Latent heat Lighting Office equipment. 0.8. 0.6. Chinese method Japanese method. 0.4 0.2 0 9. 61 73 11 20. 12. 14. Time(Unit:h). 69 53 20 16 20. Cooling Load(Unit:W). gain, [W/㎡] 1 Xτ-T (Unit:-). N E S W. Chinese Method. Japanese Method. change rate. 3,000. 1.2. intensity, [W/㎡] 9 o'clock Chinese Japanese 103 42 452 491 99 77 100 42 14 o'clock Chinese Japanese 133 42 164 42 165 108 314 400. 9 o'clock 12 o'clock Chinese Japanese Chinese Japanese 4 4 5 6 7 9 9 14 5 4 6 7 7 4 7 5 14 o'clock 16 o'clock Chinese Japanese Chinese Japanese 5 7 6 8 10 10 11 13 7 10 8 12 7 7 8 12 35% 30%. 2,500. 25% 2,000. 20%. 1,500. 15% 10%. 1,000. 5% 500. Chinge rate(Unit:-). The. 0%. 0. -5% 9. 12. 14. 16. Time(Unit:h). Fig. 3 Calculation result for external (Cooling load). 20,000 18,000 16,000 14,000 12,000 10,000 8,000 6,000 4,000 2,000 0. 90% 80% 70%. 60% 50% 40%. 30% 20% 10%. 35,000. 12. 14. 25000. Equipment. 30,000. 20000. 25,000. Human Body. 20,000. 15,000. Chinese method. 15000. Lighting. 10,000. 5000. 0. 16. Time(Unit:h). 0 Chinese Method. Japanese Method. Fresh air. Air infiltration. Fig. 4 Calculation result. Fig. 5 Calculation result for. Fig. 6 Calculation result for air. for windows (Cooling. internal heat generation. infiltration and fresh air. load) Human Body. (Cooling load). Lighting. Equipment. (Cooling load). 12000. 30000. Heating load(Unit:W). 1 0.8 0.6. 0.4 0.2. 0 9. 12. 14. 16. Time(Unit:h). 10000 8000. Chinese method. 6000. Japanese method 4000. 2000. 25000 20000. Chinese method. 15000. Japanese method 10000. 5000. 0. 0. Wall. Fig. 7 Changing of “Xτ—T”. Heating load(Unit:W). 1.2. Xτ-T. Japanese method. 10000. 5,000. 0% 9. 30000. Cooling load(Unit:W). Japanese Method. Cooling Load(Unit:W). Cooling Load(Unit:W). Chinese Method. Window. Fresh air. Air infiltration. Fig. 8 Calculation result for. Fig. 9 Calculation result for air. building body (Heating load). infiltration and fresh air (Heating. 47-3. load).

(4) 100,000. 3. Analysis of difference and Chinese method. 90,000 80,000. Cooling load[W]. improvement. 3.1 Existing difference analysis. There were some difference between the Chinese. 70,000 60,000. Air infiltration. 50,000. Fresh air. 40,000. internal heat generation. 30,000. method and the Japanese method by analyzing the. 20,000. thermal load calculation results. In the cooling load. 0. Building body. 10,000 Chinese method. Japanese method. Fig. 10 The calculation result for total cooling load. calculation result for walls, it’s easy to see that the result. 60,000. by Japanese method is about 30% bigger than by Chinese Heating load [W]. 50,000. method, and it’s opposite with the situation in the cooling load calculation for windows. The difference was by the different setting parameters, and the reason could refer. 40,000. Fresh air 30,000 Air infiltration 20,000 Building body 10,000. table 4 and table 5.. 0. In the calculation for internal heat generation, the heat. Chinese method. Japanese method. Fig. 11 The calculation result for total heating load. gain of human body was determined by the indoor. 1) To use a hourly thermal load calculation in the. headcount, the difference was product by the different. cooling load calculation for building body. 2 ) To. headcount conversions. And it’s 4 ㎡/person (Chinese. consider about the simultaneity usage coefficient in the. method) and 0.15person/ ㎡. (Japanese method). same application room. 3 ) To consider about the. respectively, therefore, the indoor headcount was 207 in. difference rate in different application rooms or. Chinese method and it was 124 in Japanese method.. buildings.. In the calculation for fresh air different setting. 4. Conclusion and prospect.. conditions make the result different, such as the volumes. 4.1 Conclusion.. of air change, indoor headcount and the setting value of. The thermal load calculation result for every element. enthalpy, and in this calculation only consider air. was different but the result for total cooling load and the. infiltration affected by gaps of windows.. total heating load was very close between the Chinese. In the heating load calculations, the meteorological. method and the Japanese method. And the primary. conditions affect the calculation result directly.. differences have been found, such as different setting. 3.2 .Improvement of Chinese method.. condition or different correction coefficient.. There were some weak points in Chinese method such. The difference between Chinese and Japanese method. as the excessive design thermal load and calculation. could be found by analyzing the thermal load calculation. parameter was used. In Chinese method, there were so. process and result, and the existing differences were. many correction factors in the thermal load calculation. caused by different design situation.. process, and these factors cannot ensure the calculation. 4.2 Prospect.. result be appropriate. And the old setting parameters. To analyze the impact factors in the thermal load. were used in the Chinese method, such as the parameters. calculation and build more models to test the result. Then. of old lighting device and office equipment. Therefore, in. revise those impact factors by using the dynamic. the Chinese method, it’s always to see that the low. calculation method. To find a better way of optimize the. efficiency device or unreasonable window-wall ratio was. steady-state thermal load calculation method in final.. used, and the excessive area window increasing the air. 【Reference】 1) 小塩真奈美他:建物空調システムの最大負荷計算と設計法に関する研究(第 1 報), 空気調和・衛生工学会大会学術講演論文集,pp.1603-1606,2010 年 9 月. 2)实用供热空调设计手册(第二版)陆耀庆 主编,中国建筑工业出版社,2008 年. 3)建築設備設計基準,國土交通省大臣官房官厅繕部設備·環境課監修,2006 年版. 4)中国建筑用标准气象数据库,张晴原 编著 机械工业出版社,2004 年 7 月.. infiltration and the radiation heat. Therefore, here were 3 improve method:. 47-4.

(5)

図

関連したドキュメント

So, the aim of this study is to analyze, numerically, the combined effect of thermal radiation and viscous dissipation on steady MHD flow and heat transfer of an upper-convected

In order to compute the Taylor tower of Hochschild homology it was natural to first consider the Taylor tower of the forgetful functor from simplicial commutative augmented

We have described the classical loss network model similar to that of Kelly [9]. It also arises in variety of different contexts. Appropriate choices of A and C for the

Exact controllability for the linear wave equation, with both controls in the interior and on the boundary, has been studied by the author in [6] and feedback laws were

The exact controllability of a semilinear wave equation in a bounded open domain of R n , with controls on a part of the boundary and in the interior, is shown.. Feedback laws

Then the change of variables, or area formula holds for f provided removing from counting into the multiplicity function the set where f is not approximately H¨ older continuous1.

• We constructed the representaion of M 1,1 on the space of the Jacobi diagrams on , and we gave a formula for the calculation of the Casson-Walker invariant of g = 1 open books.

Following Speyer, we give a non-recursive formula for the bounded octahedron recurrence using perfect matchings.. Namely, we prove that the solution of the recur- rence at some