ᯏེ㈩▤♽ߩ⚻ᐕᄌൻߦ߁⠴㔡ోᐲ⹏ଔᚻᴺߩ⎇ⓥޓႎ๔ᦠ

ਛߕߺ㧖ᄢ⼱┨ੳ㧖㧖⊕㠽ᱜ᮸㧖㧖㧖

Study on Estimation Method of Seismic Safety Margin of Aged Piping System and Equipment

Izumi NAKAMURA*, Akihito OTANI**, and Masaki SHIRATORI***

* National Research Institute for Earth Science and Disaster Prevention, Japan

** Ishikawajima-Harima Heavy Industries Co., Ltd., Japan

*** Yokohama National University, Japan

Abstract

ޓޓ㧖㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲޓ✚ว㒐ἴ⎇ⓥㇱ㐷

ޓ㧖㧖⍹Ꮉፉ⏴㊀Ꮏᬺᩣᑼળ␠ޓේሶജᬺㇱ

㧖㧖㧖ᮮᵿ࿖┙ᄢቇᄢቇ㒮ޓᎿቇ⎇ⓥ㒮

In order to clarify the behavior of degraded pipes under seismic events, cyclic four-point bending tests on straight pipe and shaking table tests using piping system models were conducted. The degradation used in this study were wall thinning or cracks, which were considered to be caused in piping systems due to the effects of aging. Cyclic bending tests were conducted on straight pipe elements to investigate the relation between the failure mode and degradation condition. Shaking table tests were also conducted to investigate the influence of degradation on piping system behavior and clarify the failure mode of degraded piping systems. Through these tests, the failure modes of aged piping were obtained under varying loading and degradation conditions.

In addition to these experiments, elastic-plastic FEM analysis using ABAQUS were conducted on pipe elements with wall thinning or a crack. It has been found that the failure modes observed in the tests were well simulated by this analysis. With this analysis, the strain concentrated point could be predicted and the cause of its generation could be explained by the simulated deformation behavior of the pipe.

In order to predict the piping system’s maximum response under elastic-plastic response, a simple response prediction method was proposed in this report. This method takes account of the dissipation energy caused by plastic deformation. It has been found that this prediction method provided a conservative value compared with the test results, but not too conservative a value as an elastic response analysis.

Key Words : Aging effect, Piping, Cracks, Wall thinning, Shaking table test, Failure mode, FEM analysis, Simple elastic-plastic response prediction method

* ** ***

4.㈩▤ⷐ⚛ߦኻߔࠆ⚦⸃ᨆ 36

4.1ᧄ┨ߩ⋡⊛߅ࠃ߮᭴ᚑ 36

4.2ዪᚲ⊛ᷫ⡺ㇱࠍߔࠆ㈩▤ߩ⸃ᨆ⊛∋ഭ⹏ଔ1㧔⋥▤㧕 36

4.2.1ታ㛎ⷐ 36

4.2.2⸃ᨆࡕ࠺࡞ߣ᧦ઙ 36

4.2.3ታ㛎⚿ᨐߣ⸃ᨆ⚿ᨐߩᲧセ 37

4.2.4ᷫ⡺㈩▤ߩ߈ⵚ⊒↢ࡔࠞ࠾࠭ࡓߣ⎕უേ 39

4.2.5⚥Ⓧ∋ഭ៊்ೣࠍ↪ߚኼ⹏ଔ 42

1.ߪߓߦ 4

1.1⢛᥊ 4

1.2ߎࠇ߹ߢߦⴕࠊࠇߚ⎇ⓥߩ⁁ 4

1.3ᧄ⎇ⓥߩ⋡⊛ 5

2.ታ㛎ᣇᴺ 6

2.1ⷐ⚛⹜㛎 6

2.1.1⹜㛎ߩⷐ 6

2.1.2タ⩄᧦ઙ 7

2.1.3⸘᷹ 8

2.2㈩▤♽ᝄേ⹜㛎 11

2.2.1ᐔ㕙㈩▤♽ᝄേ⹜㛎 11

2.2.1.1⹜㛎ߩⷐ 11

2.2.1.2タ⩄᧦ઙ 11

2.2.1.3⸘᷹ 12

2.2.2┙㈩▤♽ᝄേ⹜㛎 14

2.2.2.1⹜㛎ߩⷐ 14

2.2.2.2タ⩄᧦ઙ 15

2.2.2.3⸘᷹ 15

3.ታ㛎⚿ᨐ 17

3.1ⷐ⚛⹜㛎 17

3.1.1߈ⵚઃ߈㈩▤ 17

3.1.1.1⎕៊⁁ᴫ 17

3.1.1.2߈ⵚઃ߈㈩▤ߩ⩄㊀ᄌᒻ․ᕈ 17

3.1.1.3SCC߈ⵚߣEDM߈ⵚߩ⎕៊ኼᲧセ 19

3.1.1.4⎕㕙⸃ᨆ 19

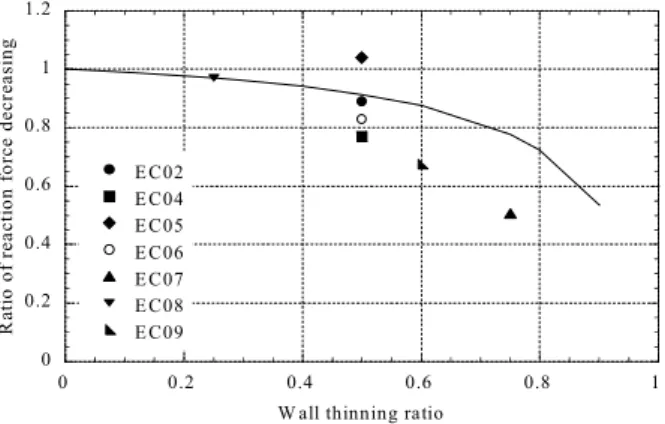

3.1.2ᷫ⡺㈩▤߅ࠃ߮ஜో㈩▤ 21

3.1.2.1⎕៊⁁ᴫ 21

3.1.2.2ᷫ⡺㊂ߣ࠴ࠚ࠶࠻ᄌᒻ㊂ߩ㑐ଥ 23

3.1.2.3ᷫ⡺㊂ߣ⹜㛎ജߩ㑐ଥ 24

3.1.2.4ஜో⹜㛎ߩ⩄㊀ᄌᒻ․ᕈ 24

3.2㈩▤♽⹜㛎 25

3.2.1ᐔ㕙㈩▤♽⹜㛎 25

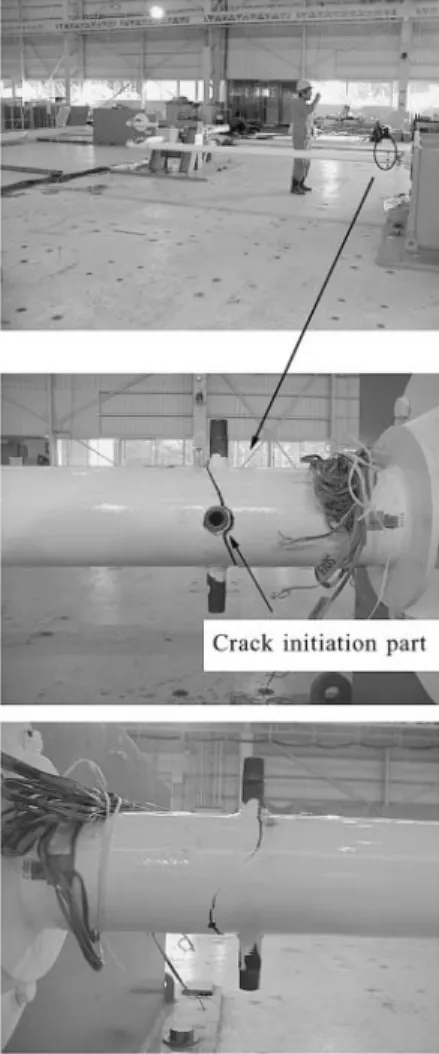

3.2.1.1⎕៊⁁ᴫ 25

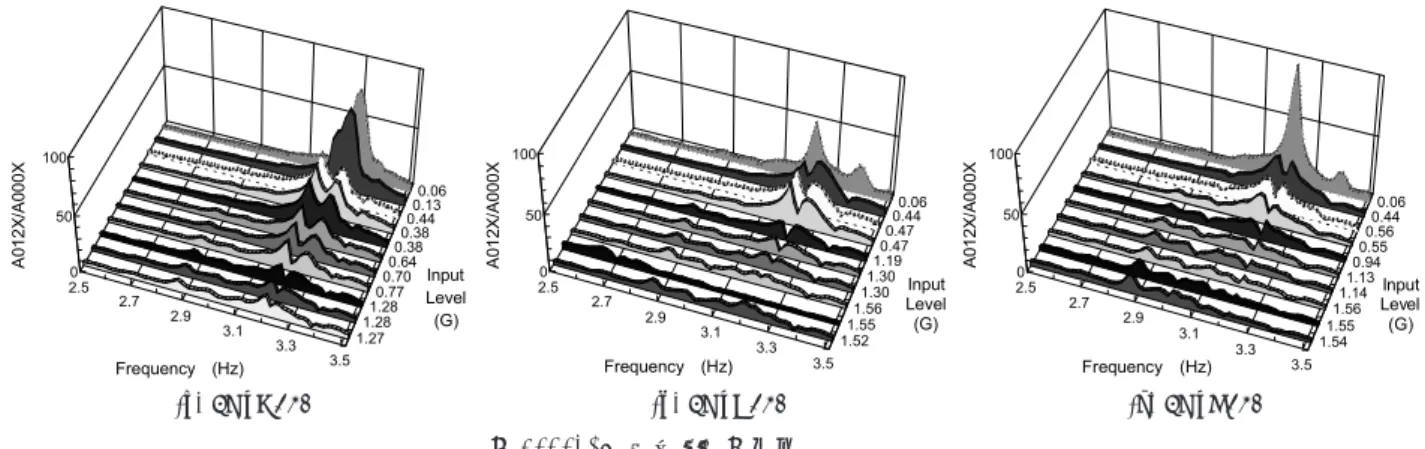

3.2.1.2ᝄേᢙߩᄌൻ 28

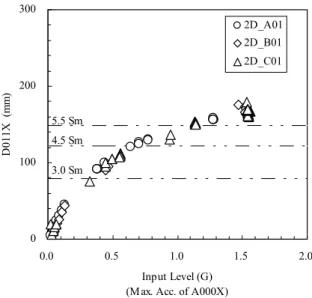

3.2.1.3ഠൻ᧦ઙߣᔕ╵୯ߩ㑐ଥ 29

3.2.1.4⹜㛎ߩᄖᓘᄌൻ 30

3.2.2┙㈩▤♽⹜㛎 31

3.2.2.1⎕៊⁁ᴫ 31

3.2.2.2ഠൻ᧦ઙߣᔕ╵୯ߩ㑐ଥ 34

3.2.2.3ࠛ࡞ࡏߩᄖᓘᄌൻ 35

4.3ዪᚲ⊛ᷫ⡺ㇱࠍߔࠆ㈩▤ߩ⸃ᨆ2㧔ᦛ▤㧕 47

4.3.1⸃ᨆࡕ࠺࡞ߣ᧦ઙ 47

4.3.2ࠛ࡞ࡏ㈩▤ߩ߈ⵚ⊒↢ࡔࠞ࠾࠭ࡓߣ⎕უേ 49

4.3.3Shellࡕ࠺࡞ߦࠃࠆ◲ᤃ⸃ᨆᚻᴺ 51

4.4㕙߈ⵚઃ߈㈩▤ߩૐࠨࠗࠢ࡞∋ഭ߈ⵚㅴዷ⹏ଔ 53

4.4.1ࠗࡦࠬࡊࡦࠣⷐ⚛ࠍ↪ߚ߈ⵚㅴዷ⸃ᨆ 53

4.4.1.1ࠗࡦࠬࡊࡦࠣⷐ⚛ 53

4.4.1.2➅ࠅߒJⓍಽ▸࿐∆ Jߩ⹏ଔ 53

4.4.1.3߈ⵚㅴዷೣ 53

4.4.1.4߈ⵚㅴዷߩ⹏ଔᚻ㗅 53

4.4.2⸃ᨆࡕ࠺࡞ߣ᧦ઙ 54

4.4.3⸃ᨆ⚿ᨐߣ⠨ኤ 55

4.5ᧄ┨ߩ߹ߣ 59

ޣၫ╩ᜂᒰޤ

╙1┨ޓ㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲޓਛޓߕߺ

╙2┨ޓ㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲޓਛޓߕߺ

╙3┨

3.1ޓ㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲޓਛޓߕߺ 3.2.1⍹Ꮉፉ⏴㊀Ꮏᬺޓޓᄢ⼱ޓ┨ੳ ޓ3.2.2㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲޓਛޓߕߺ

╙4┨ޓᮮᵿ࿖┙ᄢቇޓޓޓޓ⊕㠽ޓᱜ᮸

╙5┨ޓ⍹Ꮉፉ⏴㊀Ꮏᬺޓޓᄢ⼱ޓ┨ੳ

╙6┨ޓ㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲޓਛޓߕߺ

╙7┨ޓ㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲޓਛޓߕߺ

5.㈩▤♽ߩേ⊛ᔕ╵ߦኻߔࠆ⹏ଔ 60

5.1ⷐ 60

5.2ᒢ႟ᕈᔕ╵੍᷹ᚻᴺߩᔨ 60

5.3 ᒢ႟ᕈᔕ╵੍᷹ᚻᴺߩ⸘▚ߩ⚦ 61

5.3.1ᶖᢔࠛࡀ࡞ࠡࠍ᳞ࠆߚߩFEM⸃ᨆ 61

5.3.2ᝄേࡕ࠼⸃ᨆ 62

5.3.3ᝄേᔕ╵⸃ᨆ 63

5.3.4╬ଔᷫᲧ߮ᦨᄢᔕ╵㊂ߩ⸘▚ 65

5.4ᒢ႟ᕈᔕ╵੍᷹⚿ᨐ 65

6.߹ߣ 67

7.ߣ߇߈ 67

㧨⻢ㄉ㧪 67

㧨ෳ⠨ᢥ₂㧪 68

㧨㑐ㅪ⊒⺰ᢥ㧪 70

ⷐޓᣦ 71

㧨ᷝઃ1㧪ޓޟᯏེ㈩▤♽ߩ⚻ᐕᄌൻߦ߁⠴㔡ోᐲ⹏ଔᚻᴺߩ⎇ⓥޠታ㛎ታᣉᆔຬળޓฬ★ 72

㧨ᷝઃ2㧪ޓታ㛎⚿ᨐ╬ࠞ࿑ ޓ 73

0 1 2 3 4 5 6

1960 1963 1966 1969 1972 1975 1978 1981 1984 1987 1990 1993 1996 1999

Comercial Operation Year

Number of NPP Closed

Closed 51

ߪߓߦ

⢛᥊

ޓᚒ߇࿖ߢߪ1960ᐕߦ⊒㔚↪ේሶἹߩㆇォ߇ᆎ߹ࠅ㧘 1970ᐕߦᬺ↪ේሶἹ߇Ⓙࠍ㐿ᆎߒߚ㧚ᣣߢߪ2001 ᐕ4ߢ51ၮߩᬺ↪ේሶജ⊒㔚ᚲ߇Ⓙߒߡ߅ࠅ㧘

ේሶജߦࠃࠆ⊒㔚㊂ߪ✚⊒㔚㊂ߩ3ഀએࠍභߡࠆ㧚

৻ᣇ㧘ේሶജ⊒㔚ᚲߩㆇ↪㐿ᆎᐕߏߣߩේሶἹၮᢙߪ࿑

ߩࠃ߁ߦߥࠅ㧘ㆇ↪㐿ᆎ߆ࠄ20ᐕએ⚻ㆊߒߡࠆᣉ

⸳ߪ20ၮߣߥࠆ߇㧘ේሶജ⊒㔚ᣉ⸳ߩᣂⷙᑪ⸳ߪ෩ ߒᖱߢࠅ㧘ᣢሽߩᣉ⸳ࠍ⛽ᜬోߒߟߟ⛮⛯ߒߡ

↪ߔࠆᔅⷐ߇ࠆ㧚ේሶജ⊒㔚ᣉ⸳ߩ⠴↪ᐕᢙߪᓥ᧪

30ᐕߣߐࠇߡ߈ߚ߇㧘1999ᐕߦㅢ↥⋭⾗Ḯࠛࡀ࡞ࠡ

ᐡߪㆇォ㐿ᆎᓟ30ᐕㄭߊࠍ⚻ߚේሶജ⊒㔚ᣉ⸳3ၮߦߟ

ߡ㧘60ᐕࠍⷞ㊁ߦࠇߚ㐳ᦼㆇォ߇ᛛⴚ⊛ߦน⢻ߣߔ ࠆႎ๔ᦠ1)ࠍឭߒߚ㧚ߒ߆ߒ㧘㐳ᦼߦࠊߚߞߡ↪ߐࠇ ߚᣉ⸳ߦߪ㜞⚻ᐕൻߦ᭴ᚑᯏེ㈩▤ߩഠൻ߇⊒↢

ߔࠆߣ⠨߃ࠄࠇࠆߎߣ߆ࠄ㧘㐳ኼൻࠍታߔࠆߚߦ ߪ㧘ㆡಾߥ▤ℂࠍⴕ㧘㜞⚻ᐕൻࡊࡦ࠻ߩᡷㅧᎿࠍ

ߚ⚻ᐕൻኻ╷ࠍ⻠ߓ㧘ోᕈࠍ⏕ߔࠆᔅⷐ߇ࠆ㧚 ޓ৻⥸ߦ㧘ࡊࡦ࠻ߦ߅ߌࠆਥⷐ᭴ᚑⷐ⚛ߩ৻ߟߢࠆ

㈩▤♽ߦߪޔ㜞⚻ᐕൻߦࠃࠅㅢᏱߩᾲ∋ഭߛߌߢߥߊޔᔕ ജ⣣㘩ഀࠇ߿⣣㘩უ㘩ߥߤߦࠃࠆᷫ⡺ߣߞߚഠൻ߇

⊒↢ߔࠆߎߣ߇⍮ࠄࠇߡࠆ㧚㊀ⷐᐲߩ㜞㈩▤♽ߦ⎕

უ߇↢ߓߚ႐ว㧘ࠪࠬ࠹ࡓోߦᵄߔࠆᓇ㗀߇ᄙᄢߢ

ࠆߎߣ߆ࠄ㧘ߘߩஜోᕈࠍ⛽ᜬߔࠆߎߣߪ㊀ⷐߢࠆ㧚

․ߦᣣᧄߪ㔡࿖ߢࠆߚ㧘ഠൻࠍᗐቯߒߚ㜞⚻ᐕࡊ

ࡦ࠻ߩోᕈߪᄢ㔡ᤨߦ߅ߡ߽චಽ⏕ߐࠇߥߌ ࠇ߫ߥࠄߥ㧚㈩▤♽ߦ⊒↢ߔࠆᷫ⡺߿߈ⵚߩࠃ߁ߥഠ ൻߩ⸵ኈഠൻၮḰߩᬌ⸛ߦ߅ߡߪ㧘ታ㛎߿⸃ᨆߦၮߠ ߊวℂ⊛ߥᬌ⸽࠺࠲ࠍ⫾Ⓧߔࠆᔅⷐ߇ࠆ㧚߹ߚ㧘ᣣᧄ ߪ㔡࿖ߢࠆߚ㧘ߘߩࠃ߁ߥഠൻ߇ᬌߐࠇߚ႐ว

ߩ㊀ⷐߥ㗴ߩ৻ߟߣߒߡ㧘ᒰഠൻ⁁ᴫ߇⠴㔡⸵ኈ ߐࠇࠆ߆ߤ߁߆ߩ⹏ଔ߇ᔅⷐߢࠆ㧚ߘߩߚߦߪߎߩ ࠃ߁ߥഠൻㇱ߇㈩▤♽ߩേ⊛േ߅ࠃ߮⠴㔡ోᐲߦ ਈ߃ࠆᓇ㗀ࠍࠄ߆ߦߒ㧘㔡േࠍฃߌࠆ⚻ᐕഠൻ㈩▤

ߩേࠍวℂ⊛ߦ⹏ଔߔࠆᚻᴺ߇ᔅⷐߣߥࠆ㧚 ߎࠇ߹ߢߦⴕࠊࠇߚ⎇ⓥߩ⁁

ޓഠൻㇱࠍߔࠆ㈩▤♽ߩஜోᕈ⹏ଔ߿⠴㔡ోᐲߦ 㑐ߔࠆ⎇ⓥߣߒߡߪ㧘ߎࠇ߹ߢߦ߈ⵚઃ߈㈩▤ࠍኻ⽎ߣ ߒߡ㧘ᄙߊߩ⎇ⓥ߇ⴕࠊࠇߡ߈ߚ㧚ᣣᧄේሶജ⎇ⓥᚲߢ

ߪ㧘1ᰴ಄ළ㈩▤ߦߟߡ᭴ㅧᒝᐲߩା㗬ᕈࠍታ㛎⊛ߦ

ᬌ⸽ߔࠆߎߣࠍ⋡⊛ߣߒߡ㧘1975ᐕ߆ࠄ1992ᐕߦ߆ߌߡ

㈩▤ା㗬ᕈታ⸽⹜㛎߇ታᣉߐࠇߚ2)㧚ߎߩ⹜㛎⎇ⓥߢߪ㧘 ਥߦ߈ⵚઃ߈㈩▤ࠍኻ⽎ߣߒߡ㧘㈩▤∋ഭ⹜㛎㧘ਇቯ⎕

უ⹜㛎㧘⎕ᢿ⹜㛎㧘⸃ᨆ⹏ଔ߇ታᣉߐࠇߚ㧚߹ߚ㧘⎇ⓥᦼ 㑆ਛߩ1986ᐕߦ☨࿖Surryේሶജ⊒㔚ᚲߢᷫ⡺ࠛ࡞ࡏߩ⎕

ᢿ߇⊒↢ߒߚ3)ߚ㧘ᷫ⡺㈩▤ߩ⎕უ㒢⇇ࠍ᳞ࠆ⹜

㛎߽ታᣉߐࠇߚ㧚߹ߚ㧘㔚ജਛᄩ⎇ⓥᚲߢߪࠕࡔࠞේሶ ജⷙᆔຬળ㧔NRC㧕߇ਥߒߚ࿖㓙ห⎇ⓥߢࠆ߈ ⵚઃ߈㈩▤ߩஜోᕈ⹏ଔᚻᴺࠍ⏕┙ߔࠆߚߩ⎇ⓥ

㧔IPIRG㧕4)ߦෳടߒ㧘ᣣᧄ࿖ౝߩ⚛㍑㈩▤ߦኻߔࠆታᢿ 㕙ᔕജၮḰߩㆡ↪ᕈߩᬌ⸛㧘േ⊛➅ࠅߒ⩄㊀ਅߦ߅ߌ ࠆ߈ⵚㅴዷ⹏ଔߥߤߩ⎇ⓥࠍታᣉߒߚ5)㧚

ᷫ⡺ߩࠃ߁ߥ㕖߈ⵚ⁁ᰳ㒱ߩஜోᕈ⹏ଔߦኻߒߡߪ㧘 ᄢቇ߿᳃㑆ડᬺߦࠃࠅᷫ⡺ࠍᮨᡆߒߚ㈩▤ߩ⚳ዪᒝᐲ߿

⎕უᒻᘒࠍᓧࠆታ㛎⎇ⓥ߇ታᣉߐࠇᆎ6)-8)㧘ഠൻᒻ⁁ߣ

⎕៊᧦ઙߣߩ㑐ㅪߠߌ߇ⴕࠊࠇߡࠆ㧚߹ߚ㧘ේሶജ⊒㔚 ᛛⴚᯏ᭴㧔NUPEC㧕ߢߪ㧘ᐔᚑ12ᐕᐲࠃࠅᐔᚑ17ᐕᐲ߹

ߢߩ੍ቯߢ㧘ᷫ⡺㈩▤ߩ⠴㔡ታ⸽⹜㛎ࠍታᣉߒߡࠆ9)㧚 ߒ߆ߒ㧘ోߣߒߡߪഠൻ᧦ઙߣߒߡᷫ⡺ࠍኻ⽎ߣߒߚ

㈩▤ߩ⠴㔡ోᕈ⹏ଔߦ㑐ߔࠆ⎇ⓥߪ߹ߛᢙ߇ዋߥ㧚

࿑ ᣣᧄߦ߅ߌࠆᬺ↪ේሶἹߩㆇ↪㐿ᆎᐕߏߣߩၮᢙ

Fig.1-1 Numbers of Nuclear Power Plants in commercial operation (Japan).

ᄢࡌ࡞ߩ㔡ࠍᗐቯߒߚ㈩▤♽ߩᒢ႟ᕈᔕ╵ߦ㑐ߔࠆ

⎇ⓥߪ㧘ஜో㈩▤ࠍኻ⽎ߣߒߚ߽ߩ߇ਥߢࠅ㧘ഠൻ㈩▤

ߦ߅ߌࠆ⚳ዪᒝᐲ߿⎕៊ᒻᘒࠍኻ⽎ߣߒߚ߽ߩߪ㧘⸥

ߩNUPECߢᓟታᣉߔࠆ੍ቯߩ⎇ⓥ⺖㗴એᄖߦߪ߶ߣࠎ ߤฃߌࠄࠇߥ㧚ஜో㈩▤♽ࠍኻ⽎ߣߒߚ߽ߩߣߒߡ ߪ㧘1971ᐕ㨪1973ᐕߦታᣉߐࠇߚ㧘㔡ᤨߦ߅ߌࠆේሶ ജᣉ⸳ߩ㒢⇇⸳⸘ߦ㑐ߔࠆ⹜㛎⎇ⓥ㧔ᣣᧄ㔚᳇දળ㧕10)㧘

㈩▤⠴㔡⸳⸘ၮḰߩวℂൻ⎇ⓥ㧔㔚ജㅢ⎇ⓥ㧕11)߿㧘 NUPECߦࠃࠅታᣉߐࠇߡࠆ㈩▤ߩ⚳ዪᒝᐲ⠴㔡ታ⸽⹜

㛎12)߇ߍࠄࠇࠆ㧚߹ߚ㧘ᶏᄖߢⴕࠊࠇߡࠆ⎇ⓥߣߒ ߡ㧘☨࿖ߩEPRIߢታᣉߐࠇߚ㈩▤ߩേ⊛ା㗬ᕈ⹏ଔߦ㑐 ߔࠆ⎇ⓥࡊࡠࠣࡓ㧔PFDRP㧕13)߇ࠅ㧘ߎߩታ㛎⚿ᨐ

߿⸃ᨆ⚿ᨐ߆ࠄ㧘㈩▤♽ߩ⚳ዪ⎕៊ᒻᘒ߿⸳⸘ၮḰᄌᦝ ߦ㑐ߔࠆ⼏⺰߇ⴕࠊࠇߡࠆ14)㧚߹ߚ㧘ࡈࡦࠬߢߪේሶ ജᐡ㧔CEA㧕ߦࠃࠅ㧘ၮḰߩ✭ࠍ⋡⊛ߣߒߡ㧘ታⷙᮨߩ

㈩▤ࠍ↪ߚᝄേ⎕უታ㛎ߣ㧘◲ᤃ⸃ᨆࠦ࠼ߩ㐿⊒߇ ⴕࠊࠇߚ15)㧚

ᧄ⎇ⓥߩ⋡⊛

⢛᥊ߢㅀߴߚࠃ߁ߦ㧘㜞⚻ᐕ㈩▤♽ߩᄢ㔡ᤨߦ߅ߌ ࠆోᐲࠍวℂ⊛ߦ⹏ଔߔࠆߚߦߪ㧘ߘߩࠃ߁ߥ㈩

▤♽ߩ㒢⇇ᒝᐲ߿ᦨ⚳⎕៊ᒻᘒࠍᛠីߔࠆᔅⷐ߇ࠆ㧚 ߒ߆ߒ㧘߈ⵚ߿ᷫ⡺ߣߞߚ᭴ㅧഠൻ߇ࠆ㈩▤♽ߩ㕒

⊛⩄㊀ਅߦ߅ߌࠆ㒢⇇ᒝᐲߦ㑐ߔࠆ⎇ⓥ㧘ࠆߪஜో

㈩▤♽ߩᒢ႟ᕈᔕ╵ߦ㑐ߔࠆ⎇ⓥߪᢙᄙߊߥߐࠇߡࠆ ߇㧘᭴ㅧഠൻ߇ࠆ㈩▤♽ߢ㔡⩄㊀ࠍኻ⽎ߣߒ㧘㒢⇇ᒝ ᐲ߿ᒢ႟ᕈᔕ╵ࠍኻ⽎ߣߒߚ⹜㛎⎇ⓥߪ߶ߣࠎߤߥߐࠇ ߡߥ㧚ߘߎߢ㧘㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲߢߪ㧘ᮮᵿ࿖┙ᄢ ቇ㧘⍹Ꮉፉ⏴㊀Ꮏᬺߣߩਃ⠪หߢ㧘㔡േࠍฃߌࠆ⚻

ᐕഠൻ㈩▤ߩേ⊛േ߅ࠃ߮⎕៊ᒻᘒࠍታ㛎⊛ߦࠄ߆ ߦߒ㧘⚻ᐕഠൻ㈩▤ߩ⠴㔡ᕈࠍวℂ⊛ߦ⹏ଔߔࠆᚻᴺࠍ ᬌ⸛ߔࠆߎߣࠍ⋡⊛ߣߒߡ㧘ᐔᚑ8ᐕᐲ߆ࠄᐔᚑ12ᐕᐲ ߦ߆ߌߡ㧘ේሶജో⎇ⓥޟᯏེ㈩▤♽ߩ⚻ᐕᄌൻߦ

߁⠴㔡ోᐲ⹏ଔᚻᴺߩ⎇ⓥޠࠍታᣉߒߚ㧚

ᧄ⎇ⓥߢߪ㧘⚻ᐕᄌൻࠍᗐቯߒߚޔᒝᐲ⊛ߦ෩ߒᒻ

⁁ߩ߈ⵚ߹ߚߪᷫ⡺ࠍ㈩▤ࡕ࠺࡞ߦዉߒታ㛎ࠍⴕ߁ߎ ߣߦࠃࠅ㧘ഠൻᒻ⁁ߦࠃࠆ⎕៊ᒻᘒߩ㆑㧘ഠൻㇱߩή ߦࠃࠆ㈩▤♽ߩ㔡ᔕ╵ߩᄌൻ╬ࠍࠄ߆ߦߔࠆߎߣࠍ

⋡⊛ߣߒߚ㧚ߎߩߚ㧘ታ㛎ߢߪ⚻ᐕഠൻࠍᮨᡆߒߚ⋥▤

ࠍ↪ߡ➅ࠅߒ4ὐᦛߍ⹜㛎ࠍⴕ߁ⷐ⚛⹜㛎ߣ㧘ഠൻㇱ ಽࠍߔࠆ㈩▤♽ߦኻߒߡᝄേบࠍ↪ߡടᝄࠍⴕ߁㈩

▤♽ᝄേ⹜㛎ࠍታᣉߒߚ㧚߹ߚ㧘ߎࠇࠄߩታ㛎࠺࠲ߦၮ ߠ߈㧘⚦⸃ᨆߦࠃࠆ⎕៊ࡔࠞ࠾࠭ࡓߩ⠨ኤ߿ᒢ႟ᕈᔕ

╵ᄌߩ◲ᤃ੍᷹ᴺߩᬌ⸛ࠍⴕߞߚ㧚ᧄႎ๔ᦠߪ5ࡩᐕߦ ࠊߚࠅታᣉߒߚታ㛎ౝኈߣ⸃ᨆ⹏ଔߦߟߡߣࠅ߹ߣ

ߚ߽ߩߢࠆ㧚╙2┨ߢߪ㧘ᧄ⎇ⓥߢታᣉߒߚታ㛎ߩⷐ

ࠍ㧘╙3┨ߢߪታ㛎⚿ᨐߩ⇛ࠍㅀߴࠆ㧚╙4┨߅ࠃ߮╙

5┨ߢߪ㧘ߎࠇࠄߩታ㛎⚿ᨐࠍ〯߹߃ਃᯏ㑐߇ߎࠇ߹ߢታ ᣉߒߚ⸃ᨆ⹏ଔߦߟߡㅀߴࠆ㧚ߎࠇࠄߩ⸃ᨆ⹏ଔߪฦ ᯏ㑐߇ߘࠇߙࠇߩⷞὐ߆ࠄታᣉߒߚ߽ߩߦߟߡ㧘ᧄႎ ๔ᦠࠍߣࠅ߹ߣߚᤨὐߦ߅ߌࠆᬌ⸛⁁ᴫࠍㅀߴߚ߽ߩ ߢࠅ㧘⁁ߢߪᔅߕߒ߽⋧ߦㅪ៤ߩߣࠇߚ⛔৻ᕈߩ

ࠆౝኈߣߪߥߞߡߥ㧚⸃ᨆߦ߅ߌࠆⷞὐߩ⛔৻ߣ

⹏ଔᴺ߳ߩឭ᩺ߦߟߡߪᐔᚑ13ᐕᐲࠃࠅታᣉߔࠆᰴᦼ

ේሶജో⎇ⓥ㧘ޟ㔡⩄㊀ࠍฃߌࠆᷫ⡺㈩▤ߩ⎕უㆊ⒟

⸃ߦ㑐ߔࠆ⎇ⓥޠߩਛߢ⛮⛯ߒߡߊߎߣߣߒߡࠆ㧚 ߥ߅㧘ᧄ⎇ⓥߪේሶജో⎇ⓥᐕᰴ⸘↹㧔ᐔᚑ8ᐕᐲ㨪 ᐔᚑ12ᐕᐲ㧘ේሶജోᆔຬળ╷ቯ㧕16)ߦၮߠߡ߅ࠅ㧘

⑼ቇᛛⴚᐡ࿖┙ᯏ㑐ේሶജ⹜㛎⎇ⓥ⾌ࠍゲߦ㧘ฦᯏ㑐⁛

⥄ߩ⎇ⓥ⾌߽↪ߒߡታᣉߐࠇߚ߽ߩߢࠆ㧚߹ߚ㧘ᧄ⎇

ⓥߩታᣉߦߚࠅ㧘ታ㛎ታᣉᆔຬળ㧔એਅAPᆔຬળ㧘ᆔ

ຬ㐳㧦⊕㠽ᱜ᮸ᮮᵿ࿖┙ᄢቇᢎ㧕ࠍ⚵❱ߒ㧘ታ㛎ߩታᣉ㧘

⸃ᨆ⹏ଔߦߟߡ⼏⺰ࠍⴕߞߚ㧚ᧄ⎇ⓥߢߪ㔡ߦࠃࠆ

㈩▤ߩᒢ႟ᕈᔕ╵߆ࠄ㈩▤ߩ⎕៊ߦ⥋ࠆ߹ߢߩ㗔ၞࠍኻ

⽎ߣߒߚߚ㧘⎕უജቇߣᝄേᔕ╵ߩਔಽ㊁ߩኾ㐷ኅ߆ ࠄߥࠆᆔຬળߣߒߚ㧚߹ߚ㧘ታോ⊛ߥⷰὐ߆ࠄߩᗧࠍ

ߚߛߊߚ㧘㔚ജળ␠߮ࡊࡦ࠻ࡔ߽ࠞ߳ᆔຬߩ ᵷ㆜ࠍଐ㗬ߒߚ㧚ᷝઃ1ߦAPᆔຬળᆔຬฬ★ࠍ␜ߔ㧚

ታ㛎ᣇᴺ ⷐ⚛⹜㛎

⹜㛎ߩⷐ

ޓⷐ⚛⹜㛎ߢߪ㧘ഠൻᒻ⁁߿タ⩄ጁᱧߦࠃࠆ⎕៊ᒻᘒߩ

㆑ࠍ⏕ߔࠆߎߣࠍ⋡⊛ߣߒߡഠൻㇱࠍߔࠆ⋥▤ࠍ

↪ߚᄌᓮߩ4ὐᦛߍ⹜㛎ࠍⴕߞߚ㧚ᐔᚑ8ᐕᐲߦߪ タ⩄ⵝ⟎ߩࠍⴕ㧘ᐔᚑ9ᐕᐲ㨪ᐔᚑ12ᐕᐲߦ߆ߌ ߡタ⩄⹜㛎ࠍታᣉߒߚ㧚

ޓⷐ⚛⹜㛎ߢዉߒߚഠൻ᧦ઙߪ㧘ᔕജ⣣㘩ഀࠇ㧔SCC㧕㧘

㔚ടᎿ㧔EDM㧕߈ⵚ㧘߹ߚߪᷫ⡺ߩߕࠇ߆ߣߒߚ㧚߹

ߚ㧘ᷫ⡺⹜㛎ߣหߓ᧚⾰ߢஜో⡺ෘߩ⹜㛎ߦߟߡ

߽タ⩄ࠍⴕ㧘⩄㊀ᄌᒻ․ᕈߩᲧセࠍⴕߞߚ㧚㈩▤ߩ᧚⾰

ߪ㧘SCC⹜㛎߅ࠃ߮EDM߈ⵚઃ߈⹜㛎㧔એਅEDM

⹜㛎㧕ߢߪࠬ࠹ࡦࠬ㍑SUS304ࠍ㧘ᷫ⡺⹜㛎߅ࠃ߮

ஜో⹜㛎ߢߪ⚛㍑STS410ࠍ↪ߒߚ㧚ߥ߅㧘ᧄ⎇ⓥ

ߢߪ⚻ᐕᄌൻߦ߁᧚⾰ᄌൻߩᓇ㗀ߪ⠨ᘦߒߡߥ㧚 ଏ⹜ㇱߩ㈩▤ߪ100A㧘sch80㧔ᄖᓘ㧦114.3mm㧘⡺ෘ㧦8.6mm㧕 ߣߒߚ㧚߹ߚ㧘4ὐᦛߍ⹜㛎ⵝ⟎ߩᡰὐㇱಽߦ߅ߌࠆዪㇱ ᄌᒻࠍ㒐ᱛߔࠆߚ㧘ᒝ▤ߣߒߡ⹜㛎ㇱಽߩ㈩▤ߩ ਔ┵ߦ100A㧘sch160㧔ᄖᓘ㧦114.3mm㧘⡺ෘ㧦13.5mm㧕ߩ

㈩▤ࠍṁធߒߚ㧚⹜㛎ㇱಽߩ㈩▤㐳ߐߪ400mm߹ߚߪ

200mmߣߒ㧘ṁធߔࠆᒝ▤ߩ㐳ߐࠍ⺞▵ߒߡోߩ㐳

ߐࠍ3010mmߣߒߚ㧚

ޓ⹜㛎ߪ㧘SCC⹜㛎8㧘EDM⹜㛎9㧘ᷫ⡺⹜

㛎9㧘ஜో⹜㛎2ߩ⸘28ࠍߒߚ㧚ฦഠൻߩ ዉᣇᴺߣഠൻᒻ⁁ߪએਅߩㅢࠅߢࠆ㧚

(1) SCC

⹜㛎㈩▤ߦṁធࠍᣉߒߡᒁᒛᱷ⇐ᔕജࠍዉߒ㧘㜞᷷

㜞ਅߩࠝ࠻ࠢࡉౝߦ200ᤨ㑆㨪800ᤨ㑆⒟ᐲ

ᩰ⚊ߒ㧘SCCࠍ↢ᚑߐߖߚ㧚↢ᚑߒߚSCCߩ߈ⵚ⟎

ߣᷓߐߪታ㛎೨ߦᶐㅘត்㧔PT㧕ᬌᩏߢ⺞ᩏߒ㧘ᦨ

߽ᄢ߈ߣᕁࠊࠇࠆ߈ⵚ⟎߇ᦨᄢᦛߍᣇะߦ৻⥌ߔ ࠆࠃ߁⹜㛎ߩ⸳⟎⟎ࠍ⺞ᢛߒߚ㧚

ޓSCC⹜㛎ߪ⹜㛎⚳ੌᓟ㧘⎕㕙ᬌᩏࠍⴕߞߡೋᦼ SCCᒻ⁁ࠍ᷹ቯߒߚ㧚࿑ ߦ⹜㛎ߩᒻ⁁ࠍ㧘࿑ ߦSCCㇱಽߢ߈ⵚ߇⽾ㅢߒߚ⹜㛎ߩೋᦼSCC ᒻ⁁ࠍ␜ߔ㧚

(2) EDM߈ⵚ

㔚ടᎿߦࠃࠅ㈩▤ౝ㕙ߦ߈ⵚࠍዉߒߚ㧚߈ⵚᒻ⁁

ߪ㧘ౝⷺ360q߈ⵚᷓߐ4.3mm㧔⡺ෘߩ50%㧕ߩో

߈ⵚࠍᜬߟ⹜㛎ࠍ4㧘ౝⷺ90qᷓߐ4.3mmߩ⍱ᒻ ߈ⵚࠍᣉߒߚ߽ߩࠍ2㧘SCC߈ⵚࠍᮨᡆߒߚඨᬦ

߈ⵚࠍᣉߒߚ߽ߩࠍ3ߒߚ㧚ߎߎߢ㧘SCC߈ⵚ ࠍᮨᡆߒߚEDM߈ⵚઃ߈⹜㛎ߪ㧘SCCߩࠃ߁ߥ⥄

ὼ߈ⵚߣEDM߈ⵚߩࠃ߁ߥੱᎿᰳ㒱ߣߩ⎕៊ኼߩ

8.6 114.3 4.3

90q

Loading direction

6.5q 37q

13q (a) EM01 - EM04. (b) EM05, EM09.

࿑ ޓSCC⹜㛎ߩᒻ⁁

Fig.2.1-1 Geometry of the specimens with SCC.

࿑ SCC⹜㛎ߩೋᦼSCC߈ⵚᒻ⁁

Fig.2.1-2 Initial shape of SCC in SCC specimens.

࿑ EDM⹜㛎ߩᒻ⁁

Fig.2.1-3 Geometry of the specimens with an EDM notch.

࿑ EDM⹜㛎ߩೋᦼ߈ⵚᒻ⁁

Fig.2.1-4 Initial crack shapes of EDM notched pipe specimens.

(a) Initial SCC in SC01. (b) Initial SCC in SC03.

(c) Initial SCC in SC07. (d) Initial SCC in SC08.

Semieliptical EDM notch Depth : 4.25 mm Width : 21.8 mm

(c) EM06. (d) EM07. (e) EM08.

Semieliptical EDM notch Depth : 4.2 mm Width : 12.6 mm

Semieliptical EDM notch Depth : 2.9 mm Width : 14.1 mm SCC induced area

200

8.68.6 Ǿ114.3

13.5

100 100

SCC induced area 400

8.6

8.6 Ǿ114.3

13.5

200 200

(b) SC05, SC06.

(a) SC01 - SC04, SC07, SC08.

400

400

8.68.6 Ǿ114.3

13.5

200 200

EDM notch 400

㆑ࠍ⏕ߔࠆߚߦታᣉߒߚ㧚⹜㛎ߦዉߒߚ߈ ⵚߪSCC⹜㛎ߩ⎕ᢿ㕙ߦࠆೋᦼSCCᒻ⁁ࠍ㧘╬

ଔߥᷓߐߣᢿ㕙Ⓧࠍᜬߟඨᬦᒻ⁁ߩEDM߈ⵚߢᮨ

ᡆߒߚ㧚࿑ ߦ⹜㛎ߩᒻ⁁ࠍ㧘࿑ ߦዉ

ߒߚ߈ⵚᒻ⁁ࠍ␜ߔ㧚 (3)ᷫ⡺

ᯏ᪾ടᎿߦࠃࠅ㈩▤ߩ⡺ෘࠍૐᷫߒߚ㧚ᷫ⡺ߪోᷫ

⡺ߣߒ㧘ᷫ⡺㊂ߪ⡺ෘߩ50%㧔⡺ෘ4.3mm㧕ߩ߽ߩࠍ 6㧘75%ߩ߽ߩ㧔⡺ෘ2.15mm㧕㧘60%ߩ߽ߩ㧔⡺ෘ

3.44mm㧕㧘25%ߩ߽ߩ㧔⡺ෘ6.45mm㧕ࠍฦ1ߒ ߚ㧚࿑ ߦ⹜㛎ߩᒻ⁁ࠍ␜ߔ㧚

ޓ߹ߚ㧘ߎߩઁߦஜో⹜㛎ࠍ2ᚑߒߚ㧚ஜో⹜㛎

ߩᒻ⁁ࠍ࿑ ߦ␜ߔ㧚

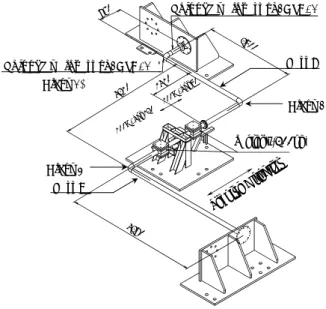

タ⩄᧦ઙ

ޓ㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲᚲߩ৻ᰴరᄢဳᝄേบࠍ↪㧘 ᝄേบߣၮ␆ߣߩ⋧ኻᄌࠍ↪ߒߚᄌᓮߩ➅ࠅ

ߒ4ὐᦛߍ⹜㛎ࠍⴕߞߚ㧚 ߦᄢဳᝄേบߩၮᧄᕈ

⢻ࠍ㧘࿑ ߦ4ὐᦛߍ⹜㛎ⵝ⟎ࠍ␜ߔ㧚4ὐᦛߍ⹜㛎 ⵝ⟎ߩᡰᜬὐࠬࡄࡦߪ2,400mm㧘⽶⩄ὐࠬࡄࡦߪ800mm ߢࠆ㧚タ⩄ጁᱧߪቯᏱᝄߦࠃࠆタ⩄ߣࡦ࠳ࡓᝄ

ߦࠃࠆタ⩄ߩ⎕უߦ߷ߔᓇ㗀ࠍᛠីߔࠆߚߦ㧘ᝄ

400

8.68.6 Ǿ114.3

13.5

400

8.6 㱂114.3

13.54.3

100 62.5 37.5

62.5 100 R200

400

8.6 㱂114.3

13.5

2.15

100 62.8 37.2

62.8 100 R200

R200

Ǿ114.3

62.5

37.5 62.5 400

6.45 13.5

R200 400

8.6

62.5

37.5 62.5

3.45 Ǿ114.3

13.5

(a) 50% thinned wall specimen (EC01 - EC06).

(b) 75% thinned wall specimen (EC07).

(c) 25% thinned wall specimen (EC08).

(d) 60% thinned wall specimen (EC09).

࿑ ᷫ⡺⹜㛎ߩᒻ⁁

Fig.2.1-5 Geometry of the specimens with wall thinning.

࿑ ޓஜో⹜㛎ߩᒻ⁁㧔EA01߅ࠃ߮EA02㧕 Fig.2.1-6 Geometry of the specimens without wall thinning (EA01 & EA02).

࿑ 4ὐᦛߍ⹜㛎ⵝ⟎

Fig.2.1-7 Four-point bending test equipment.

࿑ ജᄌᵄᒻ

Fig.2.1-8 Time histories of input displacement.

Disp.[mm]

Time[sec]

Disp.[mm]

Time[sec]

(a) Sinusoidal wave.

(b) Random amplitude wave.

Table 15.0 m 14.5 m

Weight: 160 ton Driving system Electro – hydraulic

servo control system Actuators 360 ton (90 ton 4) Max. model weight 500 ton

Max. amplitude r220 mm Max. velocity 75 cm/sec

Max. acceleration 0.55G (with 500-ton model) / 2.2G (without model) Frequency range DC – 50 Hz

Input wave typ es Sinusoidal wave Random wave Earthquake wave

ᝄേบ⻉ర

Table 2.1-1 Specification of the shaking table.

800 800

800

Anchor

Specimen

Loading Direction Shaking Table

Load Cell

Displacement meter Load Cell

߇৻ቯߢࠆᱜᒏᵄߣථᝄേᢙ߇1Hzߢࠆࡦ࠳ࡓ ᝄᵄࠍ↪ߒߚ㧚ᱜᒏᵄߪቯᏱㇱಽߩᵄᢙ߇26ᵄߢ㧘⹜

㛎ߦㆊᄢߥടㅦᐲ߇↪ߔࠆߩࠍ㒐ᱛߔࠆߚ㧘೨ᓟ 10⑽㑆ߦᝄߩẋჇẋᷫㇱࠍㅊടߒߡࠆ㧚ࡦ࠳ࡓ ᝄᵄߪේሶജᑪደߩᐥᔕ╵ࠍ㈩▤♽ߦജߒߡᓧࠄࠇ ߚᔕ╵ᄌᵄᒻࠍථᝄേᢙ߇1Hzߣߥࠆࠃ߁ᤨ㑆ゲࠍ

⺞ᢛߔࠆߎߣߦࠃࠅᚑߒߚ㧚ࡦ࠳ࡓᝄᵄߦ߹ࠇ ࠆᵄᢙߪ46ࠨࠗࠢ࡞ߢࠆ㧚࿑ ߦߎࠇࠄߩタ⩄ᵄ ᒻࠍ␜ߔ㧚

ޓ⹜㛎ߦߪᏱ᷷᳓ߢౝࠍ⽶⩄ߒߚ㧚ౝߪ㧘SCC⹜㛎

ߣEDM⹜㛎ߢ8MPa㧘ᷫ⡺⹜㛎ߣஜో⹜㛎ߢ

11MPaߣߒߚ㧚ߚߛߒ㧘ᷫ⡺⹜㛎ߩ߁ߜ1ߦߟߡ

ߪ㧘ౝ߇⎕៊ᒻᘒߦਈ߃ࠆᓇ㗀ࠍᛠីߔࠆߚߦ㧘ౝ

߅ࠃ߮ౝㇱ᳓ߥߒߢ⹜㛎ࠍⴕߞߚ㧚ᐔᚑ12ᐕᐲߦታᣉߒ ߚ⹜㛎㧔SC07㧘SC08㧘EM08㧘EM09㧘EC08㧘EC09㧕ߦ ߟߡߪౝㇱ᳓ߩṳᵨࠍ⏕ߒߚᤨὐߢタ⩄ࠍ⚳ੌߐߖ ߚ߇㧘ߘߩઁߩ⹜㛎ߢߪ߈ⵚ⽾ㅢᓟ㧘࿑ߦ␜ߒߚ

ജᄌᵄᒻ߇⚳ੌߔࠆ߹ߢタ⩄ࠍ⛮⛯ߒߚ㧚

ታ㛎ߢ↪ߒߚ⹜㛎ߩฬ⒓㧘ഠൻ᧦ઙ㧘ౝ᧦ઙࠍ߹ߣ

ߡ ߦ␜ߔ㧚

⸘᷹

ޓታ㛎ߢߪએਅߩ㗄⋡ࠍ⸘᷹ߒߚ㧚 (1)⹜㛎߳ߩജᄌ

(2)ജ (3)ౝ

(4)⹜㛎ᄖ㕙ߩゲᣇะ߅ࠃ߮ᣇะ߭ߕߺ (5)⹜㛎ౝ㕙ߩゲᣇะ߅ࠃ߮ᣇะ߭ߕߺ㧔ஜో

⹜㛎ߣᷫ⡺⹜㛎ߩ৻ㇱ㧕

(6)߈ⵚ㐿ญᄌ㧔EDM⹜㛎ߩߺ㧕

ޓ࿑ ߦฦ⹜㛎ߩ⸘᷹ὐࠍ␜ߔ㧚ߎࠇࠄߪోߡ 500Hzߩࠨࡦࡊࡦࠣᵄᢙߢ㍳ߒߚ㧚߹ߚ㧘ᷫ⡺⹜㛎

߅ࠃ߮ஜో⹜㛎ߢߪ㧘ߎߩઁߦ⹜㛎ߩ೨ᓟߦ߅ߡ

㈩▤ᄖᓘࠍ᷹ቯߒߚ㧚

Condition of defect Name Material Sy

[MPa] Su

[MPa] Sm

[MPa] Type of defect

Full angle in circumference [deg.]

Depth of defect*

Internal pressure (P) [MPa]

SC01 SC02 SC03 SC04 SC05 SC06 SC07 SC08

SUS304 311 617 206 SCC Natural crack Natural

Crack 8

EM01 EM02 EM03 EM04

360 0.5 t

EM05 90 0.5 t

EM06 25.73*1 0.49 t*1

EM07 14.87*2 0.49 t*2

EM08 16.64*3 0.34 t*3

EM09

SUS304 311 617 206 EDM

90 0.5 t

8

EC01 EC02 EC03 EC04 EC05

11

EC06

0.5 t

0

EC07 0.75 t

EC08 0.25 t

EC09

STS410 312 470 157 Wall

thinning 360

0.6 t

11 EA01

EA02 STS410 312 470 157 No

defect 0 0 11

* ‘t’ denotes the normal pipe thickness

*1 Same size as SCC in SC01 *2 Same size as SCC in SC03 *3 Same size as SCC in SC07

ⷐ⚛⹜㛎ޓ⹜㛎৻ⷩ

Table 2.1-2 Specifications for pipe element tests.

A : Accelerometer L : Load Cell P : Pressure Gauge D : Displacement S : Strain Gauge

(Hoop & Axial at each position) 50

P01

P02

S11 S12

S13 S14 S16 S15

S17 S18

0㫦(Top)

270㫦 90㫦

180㫦(Bottom)

270㫦S24 90㫦

S23 S22 S21 A01

Ground L01 D01 South

A

A B

B

A - A B - B

50

0㫦(Top)

180㫦(Bottom)

0 (Top)

180 (Bottom)

50 50 A : Accelerometer

L : Load Cell P : Pressure Gauge D : Displacement S : Strain Gauge

(Hoop & Axial at each position) C : Crip Gauge

(2ch for EM01 - EM04 and EM06, 1ch for EM05, EM07 - EM09) A0

P01

S11

P02

C01 S12 S13 S14 S16 S15

S17 S18

S24

S23 S22 S21 Ground

L01 D01

A

A

A - A South

B - B

C - C C

㪚 B

B

(a) Measurement points of SCC specimens.

(b) Measurement points of EDM specimens.

࿑ ⷐ⚛⹜㛎⸘᷹ὐ㧔1/2㧕

Fig.2.1-9 Measurement points of specimens for pipe element tests (1/2).

0 (Top) 30 30 150

L01 D01 A01

P01 P02

㪈

S11 S12 S13 S15 S14 S16 S17

S18 S24

S23 S22 S21

Ground

S52

S53

S54 S31

S42

S43

S44 S32

S33 S34 150

S02 S01

A

A

A - A South

B - B

C - C

D - D E - E

B

B C

C D

D E

E S51

S41

180(Bottom)

A : Accelerometer L : Load Cell P : Pressure Gauge D : Displacement S : Strain Gauge

(Hoop & Axial at each position)

* S01 & S02 are measured only for EC05, EC06 and EC07

0(Top

180 (Bottom) 30 30 150

P01 P02

S11 S12

S13 S15 S14 S16 S17

S18 S24

S23 S22 S21

L01 D01 A01 Ground

S51 S52 S53

S54 S41 S31

S42

S43

S44 S32

S33 S34 150

S02 S01 A

A

A - A South

B - B

C - C

D - D E - E

B

B C

C D

D E

E G

G

F

F 100 100 S74

G - G

S64

F - F

A : Accelerometer L : Load Cell P : Pressure Gauge D : Displacement S : Strain Gauge

(Hoop & Axial at each position) (c) Measurement points of EC01 - EC07.

(d) Measurement points of EC08, EC09, EA01 and EA02.

࿑ ⷐ⚛⹜㛎⸘᷹ὐ㧔2/2㧕

Fig.2.1-9 Measurement points of specimens for pipe element tests (2/2).

㈩▤♽ᝄേ⹜㛎

㈩▤♽⹜㛎ߢߪ㧘ᝄേบߦഠൻㇱಽࠍߔࠆ㈩▤♽

ࠍ⸳⟎ߒടᝄታ㛎ࠍⴕߞߚ㧚⹜㛎ߩ⋡⊛ߪഠൻㇱಽ߇ሽ

ߔࠆ㈩▤♽ߩᝄേ․ᕈߣ⎕៊േࠍ⏕ߔࠆߎߣߢ

ࠆ㧚⹜㛎ߦߪᐔ㕙Zဳߩᐔ㕙㈩▤♽ߣ㧘┙ߜ߇ࠅㇱࠍ ᜬߟ┙Zဳߩ┙㈩▤♽ߩ2⒳㘃ࠍ↪ߒߚ㧚 ᐔ㕙㈩▤♽ᝄേ⹜㛎

⹜㛎ߩⷐ

ޓᐔ㕙㈩▤♽ᝄേ⹜㛎ߪᐔᚑ10ᐕᐲߦታᣉߒߚ㧚࿑ ߦ⹜㛎ߩᒻ⁁ࠍ␜ߔ㧚⹜㛎ߪഠൻࠍዉߔࠆㇱಽ

㧔ㇱಽA㧕ߣ㧘ഠൻࠍዉߒߥㇱಽ㧔ㇱಽB㧕ߦಽ߆ࠇ㧘

ࡈࡦࠫߢធวߒߚ㧚ߚߛߒធวㇱಽߩࡈࡦࠫߪ㐽ᱛ ߒߡࠅ㧘ㇱಽAߣㇱಽBߩ㈩▤⚻〝ߪಽ㔌ߒߡࠆ㧚ᐔ 㕙㈩▤♽⹜㛎ߢዉߒߚഠൻ᧦ઙߪ⋥▤ㇱᷫ⡺߅ࠃ߮ࠛ

࡞ࡏㇱᷫ⡺ߩ2⒳㘃ߣߒߚ㧚߹ߚ㧘Ყセߩߚߦഠൻㇱಽ

߇ߥஜో㈩▤♽⹜㛎ߦߟߡ߽ടᝄታ㛎ࠍⴕߞߚ㧚

↪ߒߚ㈩▤ߩ᧚⾰ߪోߡ⚛㍑STPT370ߢ㧘㈩▤ญᓘ ߪⷐ⚛⹜㛎ߣห᭽100Aߣߒߚ㧚⡺ෘߪ㧘⹜㛎ㇱಽߢ

ࠆㇱಽAߢߪⷐ⚛⹜㛎ߣห᭽sch80㧔⡺ෘ8.6mm㧕㧘ㇱಽB

ߢߪsch120㧔⡺ෘ11.1mm㧕ߣߒߚ㧚ㇱಽBߪߔߴߡߩ⹜

㛎ߢㅢߦ↪ߒߚ㧚⹜㛎ߩฬ⒓ߣዉഠൻ᧦ઙߪએ ਅߩㅢࠅߢࠆ㧚

(1)ޓ⹜㛎ฬ㧦2D_A01 ഠൻ᧦ઙ㧦ഠൻߥߒ (2)ޓ⹜㛎ฬ㧦2D_B01

ഠൻ᧦ઙ㧦⋥▤ㇱᷫ⡺

࿑ߦ␜ߒߚ⟎ߩ⋥▤ㇱಽߩ⡺ෘࠍᯏ᪾ട ᎿߦࠃࠅㅢᏱ⡺ෘߩ50%ߦૐᷫߒ㧘ోᷫ⡺ࠍ

ᮨᡆߒߚ㧚 (3)ޓ⹜㛎ฬ㧦2D_C01

ഠൻ᧦ઙ㧦ࠛ࡞ࡏㇱᷫ⡺

࿑ ߦ␜ߒߚࠛ࡞ࡏ1ࠍsch40ߩࠛ࡞ࡏߣߔ ࠆߎߣߦࠃࠅోᷫ⡺ࠍᮨᡆߒߚ㧚sch40ߩࠛ࡞

ࡏߩ⡺ෘߪ⒓6.0mmߢࠅ㧘ᷫ⡺㊂ߪ30%ߣ ߥࠆ㧚

ޓߦ⹜㛎ߩ․ᕈࠍ߹ߣߡ␜ߔ㧚߹ߚ㧘࿑ ߦ࿕୯⸃ᨆߢ᳞ߚ2D_A01ߩ࿕ᝄേᢙߣᝄേࡕ

࠼ࠍ␜ߔ㧚⹜㛎ߩ1ᰴ࿕ᝄേࡕ࠼ߢᡰ㈩⊛ߥᄌᒻߪ

ࠛ࡞ࡏ1㧘2㧘3ߩ㕙ౝᄌᒻߢࠅ㧘ஜో⁁ᘒߩ႐ว㧘ᦨᄢ ᔕജ߇⊒↢ߔࠆߩߪࠛ࡞ࡏ1ߣߥࠆ߇㧘ࠛ࡞ࡏ2ߩᔕജ߽

߶߷ห⒟ᐲߢߞߚ㧚 タ⩄᧦ઙ

ޓ㈩▤♽ࡕ࠺࡞ߦኻߒߡ㧘㒐ἴ⑼ቇᛛⴚ⎇ⓥᚲᚲߩ৻

ᰴరᄢဳᝄേบࠍ↪ߡടᝄታ㛎ࠍⴕߞߚ㧚ടᝄᵄᒻߪ

⹜㛎ߩ1ᰴ࿕ᝄേࡕ࠼ߩߺࠍബߔࠆߚ㧘2.5Hz 㨪3.5Hzߩ⁜Ꮺၞࡦ࠳ࡓᵄࠍᚑߒߡ↪ߒߚ㧚࿑ ߦ⁜Ꮺၞࡦ࠳ࡓᵄߩടㅦᐲᤨೞᱧᵄᒻߣᔕ╵ࠬࡍࠢ࠻

࡞ࠍ␜ߔ㧚ታ㛎ߪߎߩ⁜Ꮺၞࡦ࠳ࡓᵄߩജࡌ࡞ࠍ

Condition of defect Name Material Sy*1

[MPa]

Su*1 [MPa]

Sm*1 [MPa]

Internal pressure

(P)

[MPa] Type Configuration Defected part

2D_A01 No defect --- ---

2D_B01

Full circumferential thinning

Depth : 0.5 t*

Straight pipe near the anchor (See Fig. 2.2-1)

2D_C01

STPT370 302 473 158 11

Wall thinning

Full circumferential thinning

Depth : 0.3 t*

Elbow 1

* ‘t’ denotes the normal pipe thickness

ᐔ㕙㈩▤♽⹜㛎ޓ⹜㛎৻ⷩ

Table 2.2-1 Specimens for 2-D piping system tests.

࿑ ᐔ㕙㈩▤♽⹜㛎ޓ⹜㛎ᒻ⁁

Fig.2.2-1 2-D piping model for piping system test.

Thinned wall part of B01

Thinned wall part of C01

Weight (200kg)

760

2900

Shaking Direction

4210 1410

100A, Sch120 100A, Sch80

4270

Part A

Part B (Elbow1)

Elbow2

Elbow3

Thinned wall part of 2D_C01

Thinned wall part of 2D_B01

ᒢᕈࡌ࡞߆ࠄᦨᄢ1600Gal⒟ᐲ߹ߢჇടߐߖ㧘ฦജ

ࡌ࡞ߢߩᔕ╵ᕈ⁁ࠍᓧࠆߣߣ߽ߦᦨᄢࡌ࡞ߢ⹜㛎߇

⎕៊ߔࠆ߹ߢജࠍ➅ࠅߒߚ㧚ஜో㈩▤♽⹜㛎ߦߟ

ߡߪฦടᝄࡌ࡞ߢ5࿁ߕߟടᝄࠍⴕ㧘ᔕ╵ᕈ⁁ࠍᓧ ߚߩߺߢ⎕៊ߐߖߕߦ⹜㛎ࠍ⚳ੌߐߖߚ㧚

ޓ⹜㛎ߩㇱಽAߦߪᏱ᷷᳓ࠍḩߚߒ㧘ౝࠍ⽶⩄ߒߚ㧚

ౝߪߔߴߡߩ⹜㛎ߢ11MPaߣߒߚ㧚ㇱಽBߪౝߥ ߒ㧔ౝㇱ᳓ߥߒ㧕ߢ⹜㛎ࠍⴕߞߚ㧚⹜㛎ߢߪ㧘⹜㛎߇៊

்ߒౝㇱ᳓ߩṳᵨࠍ⋡ⷞ⏕ߒߚᤨὐߢᝄേบߩജࠍ

⚳ੌߐߖߚ㧚

⸘᷹

ޓታ㛎ߢߪએਅߩ㗄⋡ࠍ⸘᷹ߒߚ㧚 (1) ᝄേบടㅦᐲ

(2) ⹜㛎ߩᔕ╵ടㅦᐲ (3) ਛᄩㇱᔕ╵ᄌ

(4) ౝ

(5) ⹜㛎ᄖ㕙ߩゲᣇะ߅ࠃ߮ᣇะ߭ߕߺ ޓ࿑ߦ⹜㛎ߩ⸘᷹ὐࠍ␜ߔ㧚ߎࠇࠄߪోߡ500Hz ߩࠨࡦࡊࡦࠣᵄᢙߢ㍳ߒߚ㧚߹ߚ㧘ߎߩઁߦ㧘⹜㛎 ߩ೨ᓟߦ߅ߡࠛ࡞ࡏㇱಽ߅ࠃ߮ᷫ⡺ዉㇱಽߩ㈩▤ᄖ ᓘࠍ᷹ቯߒߚ㧚

࿑ ޓᐔ㕙㈩▤♽⹜㛎ߩᝄേࡕ࠼

Fig.2.2-2 The vibration mode of the 2-D piping model.

-100 0 -500 0 500 100 0

0 5 1 0 1 5 20 25 30

Acc.[Gal]

Time[s]

0 5 10 15 20

0 1 2 3 4 5

Magnification of Response Acc.[Gal/Gal]

Frequency [Hz]

h=0.005 h=0.01

h=0.02 h=0.05

h=0.10 h=0.15

h=0.20 h=0.25

1st mode : 3.2Hz 2nd mode : 5.7Hz 3rd mode : 14.3Hz Shaking direction

(a) Time history of input acceleration.

(b) Response spectrum (h: damping ratio).

࿑ ޓᐔ㕙㈩▤♽⹜㛎ߢ↪ߒߚ⁜Ꮺၞࡦ࠳ࡓᵄ Fig.2.2-3 Narrow band random wave used for the piping system test of the 2-D piping model.

S014 S013

S012

S011

A011

㪉㪐㪇㪇

A002 A001

(Shaking direction and vertical direction) D011

P01 A012

A013 S024 S023

S022

S021 S034 S033

S032

S031

S043

S042

S041 S044

S054 S053

S052

S051

S074 S068 S066 S065S064

S067S063

S062S061

S073

S072

S071 S084 S083

S082

S081 S098 S097 S096 S095S094S093

S092S091

S108 S107 S106 S105S104S103

S102S101

S118 S117 S116 S115S114S113

S112S111 Accelerometer Displacement Strain gauge (Axial direction) Strain gauge (Hoop direction) A-A ࿑ޓᐔ㕙㈩▤♽⹜㛎ޓ⸘᷹ὐ Fig.2.2-4 Measurement points of the 2-D piping model.

┙㈩▤♽ᝄേ⹜㛎

⹜㛎ߩⷐ

ޓᐔᚑ11ᐕᐲ߅ࠃ߮ᐔᚑ12ᐕᐲߦ㧘┙㈩▤♽⹜㛎ࠍ

↪ߚടᝄታ㛎ࠍታᣉߒߚ㧚࿑ߦ⹜㛎ߩᒻ⁁ࠍ␜

ߔ㧚⹜㛎ߪࠛ࡞ࡏ1ࠍㇱಽ㧔ㇱಽA㧕㧘ࠛ࡞ࡏ2ࠍ

ㇱಽ㧔ㇱಽB㧕㧘ࠛ࡞ࡏ3ࠍㇱಽ㧔ㇱಽC㧕ߩ3ߟ߆ ࠄᚑࠅ㧘ࡈࡦࠫߢធวߒߚ㧚┙㈩▤♽⹜㛎ߪㇱಽ

A㧘B㧘C߇ߟߥ߇ࠅ৻ߟߩ㈩▤⚻〝ߣߥߞߡࠆ㧚┙

㈩▤♽ߢዉߒߚഠൻ᧦ઙߪ㧘ࠛ࡞ࡏㇱᷫ⡺߹ߚEDM߈ ⵚߩ2⒳㘃ߣߒߚ㧚ᐔ㕙㈩▤♽⹜㛎ߣห᭽㧘ഠൻㇱಽߩߥ

ஜో㈩▤♽⹜㛎ߦߟߡ߽ടᝄታ㛎ࠍⴕߞߚ㧚⸳ቯ ߔࠆഠൻ᧦ઙߦᓥㇱಽA߹ߚߪㇱಽBߩ㈩▤ߩ৻ㇱߦ ഠൻࠍዉߒߚ㧚ㇱಽCߪోߡߩ⹜㛎ߢㅢߦ↪ߒ

ߚ㧚

ޓ㈩▤ߩ᧚⾰ߪၮᧄ⊛ߦᐔ㕙㈩▤♽ߣห᭽㧘⚛㍑

STPT370ߣߒߚ߇㧘ᷫ⡺ࠛ࡞ࡏߪ⚛㍑㈩▤FSGPࠛ࡞ࡏ ߢઍ↪ߒߚߚࠛ࡞ࡏㇱᷫ⡺⹜㛎ߢߪᷫ⡺ࠛ࡞ࡏㇱಽ ߩߺ᧚⾰߇⇣ߥߞߡࠆ㧚߹ߚ㧘EDM߈ⵚઃ߈⹜㛎ߢ ߪ߈ⵚዉㇱಽߩ㈩▤ߦࠬ࠹ࡦࠬ㍑SUS304ࠍ↪ߒ ߚ㧚㈩▤ญᓘߪ100A㧘sch80ߣߒߚ㧚⹜㛎ߩฬ⒓ߣዉ

ഠൻ᧦ઙߪએਅߩㅢࠅߢࠆ㧚 (1) ⹜㛎ฬ㧦3D_A01

ഠൻ᧦ઙ㧦ഠൻߥߒ (2)ޓ⹜㛎ฬ㧦3D_C01

ഠൻ᧦ઙ㧦ࠛ࡞ࡏ1߅ࠃ߮ࠛ࡞ࡏ2ᷫ⡺

࿑ ߦ␜ߒߚࠛ࡞ࡏ1߅ࠃ߮ࠛ࡞ࡏ2ㇱಽࠍ FSGPࠛ࡞ࡏߣߔࠆߎߣߦࠃࠅోᷫ⡺ࠍᮨᡆߒ ߚ㧚FSGPࠛ࡞ࡏߩ⡺ෘߪ⒓4.5mmߢࠅ㧘ᷫ

⡺㊂ߪ48%ߣߥࠆ㧚 (3)ޓ⹜㛎ฬ㧦3D_C02

ഠൻ᧦ઙ㧦ࠛ࡞ࡏ1ᷫ⡺

ࠛ࡞ࡏ1ࠍFSGPࠛ࡞ࡏߣߔࠆߎߣߦࠃࠅᷫ⡺㊂ 48%ߩోᷫ⡺ࠍᮨᡆߒߚ㧚

(4)ޓ⹜㛎ฬ㧦3D_C03 ഠൻ᧦ઙ㧦ࠛ࡞ࡏ2ᷫ⡺

ࠛ࡞ࡏ2ࠍFSGPࠛ࡞ࡏߣߔࠆߎߣߦࠃࠅᷫ⡺㊂ 48%ߩోᷫ⡺ࠍᮨᡆߒߚ㧚

(5)ޓ⹜㛎ฬ㧦3D_D01

ഠൻ᧦ઙ㧦EDM߈ⵚ㧔ㇱಽ߈ⵚ㧕

࿑ߦ␜ߔࠛ࡞ࡏ1ㄭறߩ⋥▤ㇱಽߦඨᬦ

ᒻ⁁ߩEDM߈ⵚࠍዉߒߚ㧚ዉߒߚEDM߈ ⵚߩᒻ⁁ߪ㧘࿑ ߦ␜ߒߚⷐ⚛⹜㛎EM07 ߣห৻ᒻ⁁ߣߒ㧘ᦨᄢ߈ⵚᷓߐࠍᦛߍࡕࡔࡦ

3000

2600

3000 2600

Elbow1

Elbow2

Elbow3

Crack induced position Weight (200kg + 60kg)

(for 3D_D01 & 3D_D02)

Shaking direction

࿑ ┙㈩▤♽⹜㛎ޓ⹜㛎ᒻ⁁

Fig.2.2-5 3-D piping model for piping system test.

┙㈩▤♽⹜㛎ޓ⹜㛎৻ⷩ

Table 2.2-2 Specimens for 3-D piping system tests.

Condition of defect

Name Material Sy*1

[MPa]

Su*1 [MPa]

Sm*1 [MPa]

Internal pressure

(P) [MPa] Type Configuration Defected part

3D_A01 STPT370 302 473 158 10 No

defect --- ---

3D_C01

FSGP Elbow (Elbow 1 & Elbow 2)

/ STPT370 (Ordinary part)

351 452 151 Elbow 1

and Elbow 2

3D_C02

FSGP Elbow (Elbow 1) / STPT370 (Ordinary part)

351 452 151 Elbow 1

3D_C03

FSGP Elbow (Elbow 2) / STPT370 (Ordinary part)

351 452 151

10 Wall

thinning

Full circumferential thinning Depth : 0.48 t*2

Elbow 2

3D_D01 SUS304 (Part A) / STPT370 (Part B & Part C)

311 617 206 Partial EDM notch

Depth : 0.49 t*2

Full crack angle : 14.87[deg.]

3D_D02

SUS304 (Part A & Part B)

/ STPT370 (Part C)

311 617 206

8 EDM

Full circumferential EDM notch Depth : 0.5 t*2

Full crack angle : 360[deg.]

Straight pipe near Elbow 1 (See Fig. 2.2-5)

*1 Value at defected part

*2 ‘t’ denotes the normal pipe thickness

࠻߇ᦨᄢߣߥࠆᣇะ㧔Zゲ㧗ᣇะ㧕ߦ৻⥌ߐߖߚ㧚 (6)ޓ⹜㛎ฬ㧦3D_D02

ഠൻ᧦ઙ㧦EDM߈ⵚ

3D_D01ߣหߓ⟎ߩࠛ࡞ࡏ1ㄭறߩ⋥▤ㇱಽߦ

ోEDM߈ⵚࠍዉߒߚ㧚߈ⵚᷓߐߪ⡺ෘߩ

50%ߣߒߚ㧚

ޓߦ⹜㛎ߩ․ᕈࠍ߹ߣߡ␜ߔ㧚߹ߚ㧘࿑ ߦ࿕୯⸃ᨆߢ᳞ߚ3D_A01ߩ࿕ᝄേᢙߣᝄേࡕ

࠼ࠍ␜ߔ㧚⹜㛎ߩ1ᰴ࿕ᝄേࡕ࠼ߢᡰ㈩⊛ߥᄌᒻߪ

ࠛ࡞ࡏ1߅ࠃ߮2ߩ㕙ౝᄌᒻߢࠆ㧚ஜో⁁ᘒߩ႐ว㧘ᦨ ᄢᔕജ߇⊒↢ߔࠆߩߪࠛ࡞ࡏ1ߢࠅ㧘ࠛ࡞ࡏ2ߩᔕജߪ

ࠛ࡞ࡏ1ߦᲧߴ14%⒟ᐲૐ୯ߣߥߞߚ㧚 タ⩄᧦ઙ

ޓ೨㗄ߦߍߚ㈩▤♽ࡕ࠺࡞ߦኻߒߡ㧘৻ᰴరᄢဳᝄേ

บࠍ↪ߡടᝄታ㛎ࠍⴕߞߚ㧚ടᝄᵄᒻߪ⹜㛎ߩᰴ࿕

ᝄേࡕ࠼ߩߺࠍബߔࠆߚ㧘1.5Hz㨪3.0Hzߩ⁜Ꮺ

ၞࡦ࠳ࡓᵄࠍᚑߒߡ↪ߒߚ㧚࿑ߦታ㛎ߢ↪

ߚ⁜Ꮺၞࡦ࠳ࡓᵄߩടㅦᐲᤨೞᱧᵄᒻߣᔕ╵ࠬࡍࠢ࠻

࡞ࠍ␜ߔ㧚ታ㛎ߪߎߩ⁜Ꮺၞࡦ࠳ࡓᵄߩജࡌ࡞ࠍ ᒢᕈࡌ࡞߆ࠄᦨᄢ1800Gal⒟ᐲ߹ߢჇടߐߖ㧘ฦജ

ࡌ࡞ߢߩᔕ╵ᕈ⁁ࠍᓧࠆߣߣ߽ߦᦨᄢࡌ࡞ߢ⹜㛎߇

⎕៊ߔࠆ߹ߢജࠍ➅ࠅߒߚ㧚

ޓ⹜㛎ߦߪᏱ᷷᳓ࠍḩߚߒߡౝࠍ⽶⩄ߒߚ㧚ౝ୯ ߪ㧘ஜో⹜㛎߅ࠃ߮ᷫ⡺⹜㛎ߢ10MPa㧘߈ⵚߟ߈⹜

㛎ߢ8MPaߦ⸳ቯߒߚ㧚ᐔᚑ11ᐕᐲߦታᣉߒߚ⹜㛎

㧔3D_A01㧘3D_C01㧘3D_D01㧕ߦߟߡߪ㧘⹜㛎߇⎕៊

ߒౝㇱ᳓ߩṳᵨࠍ⋡ⷞ⏕ߒߚᤨὐߢᝄേบߩജࠍ⚳

ੌߐߖߚ߇㧘ᐔᚑ12ᐕᐲߦታᣉߒߚ⹜㛎㧔3D_C02㧘

3D_C03㧘3D_D02㧕ߢߪ㧘ṳᵨࠍ⏕ߒߚᓟ߽㧘࿑

ߦ␜ߒߚടㅦᐲജ߇⚳ੌߔࠆ߹ߢടᝄࠍ⛮⛯ߒߚ㧚

⸘᷹

ޓታ㛎ߢߪએਅߩ㗄⋡ࠍ⸘᷹ߒߚ㧚 (1) ᝄേบടㅦᐲ

(2) ⹜㛎߅ࠃ߮ࠕࡦࠞߩᔕ╵ടㅦᐲ (3) ࠛ࡞ࡏ1ߣࠛ࡞ࡏ2ߩ㕙ౝ㐿㐽ᄌ

࿑ ޓ┙㈩▤♽⹜㛎ߩᝄേࡕ࠼

Fig.2.2-6 The vibration mode of the 3-D piping model.

(4) ౝ

(5) ⹜㛎ᄖ㕙ߩゲᣇะ߅ࠃ߮ᣇะ߭ߕߺ (6) ࠛ࡞ࡏ3ߩ⟎ߦ߅ߌࠆਃᰴర⛘ኻᄌ

(7) ߈ⵚ㐿ญᄌ㧔߈ⵚߟ߈⹜㛎ߩߺ㧕

ޓ࿑ߦ⹜㛎ߩ⸘᷹ὐࠍ␜ߔ㧚ߎࠇࠄߪోߡ500Hz ߩࠨࡦࡊࡦࠣᵄᢙߢ㍳ߒߚ㧚߹ߚ㧘ஜో⹜㛎߅ࠃ

߮ᷫ⡺⹜㛎ߢߪ㧘ߎߩઁߦ⹜㛎ߩ೨ᓟߦ߅ߡࠛ࡞ࡏ ㇱಽߩ㈩▤ᄖᓘࠍ᷹ቯߒߚ㧚

-1000 -500 0 500 1000

0 5 10 15 20 2 5 3 0 35 40 45 50 55 6 0 65

Acc.[Gal]

Time[s]

0 5 10 15 20 25

0 1 2 3 4 5

Magnification of Response Acc.[Gal/Gal]

Frequency [Hz]

h=0.005

h=0.01 h=0.02

h=0.05 h=0.10 h=0.15

h=0.20 h=0.25 + Z

+ Y + X

Shaking direction

1st mode: 2.58Hz 2nd mode: 6.26Hz 3rd mode: 8.39Hz

(a) Time history of input acceleration.

(b) Response spectrum (h: damping ratio).

࿑ ┙㈩▤♽⹜㛎ߢ↪ߒߚ⁜Ꮺၞࡦ࠳ࡓᵄ Fig.2.2-7 Narrow band random wave used for the piping system test of the 3-D piping model.

#:

#:

#;

#<

: Accelerometer

#;

#<

: Crip gauge (for 3D_D01 & 3D_D02)

%

: Displacement

&

#<

#;

#:

#<

#

#; :

#<

#

#; :

&

510 50

500 50

&:

Z Y

X

50 100

50

100 S095

S094 S093 S091 S092 S098 S097

S096

S105 S104

S103 S102 S101 S108 S107

S106

S085 S084

S083 S082 S081 S088 S087 S013 S086

S012 S011 S014

S121 S122 S123 S124

S111 S112 S113 S114

S071 S072 S073 S074

S021 S022 S023 S024 ԙ

Ԟ Ԣ

ԟ Ԙ

Ԡ ԡ ԣ

D00

A07

D02

A01 A03

A06

#

#<

;

#:

A05

#<

A02

#

#;

:

#<

A04

#:

#;

A00 #:

(Top) (Top) (Top)

(Top)

(Top)

(Top)

(Top) (Top)

ᱡࠥࠫߪࠕࡦࠞὐ #㨪# ߦะ߆ߞߡ

ᤨ⸘ࠅޕ

┙ߜ߇ࠅ㈩▤ߪ㨆ᣇะߦะ߆ߞߡޔ㨅ࠍ ၮḰߦᤨ⸘ࠅߣߔࠆޕ

%

&

: Strain gauge (Axial) : Strain gauge (Hoop)

For 3D_D01 & 3D_D02 X

Y Z

50 50

50 500

510

: Strain gauge (45deg between axial and hoop)

S031 S038 S037

S036 S035

S034 S033 S032

S045 S044

S043 S042 S041 S048 S047

S046 S055

S054 S053 S052 S051 S058 S057

S056 S061

S062 S063 S064

Ԛ ԛ

Ԝ ԝ

C01

D01 P01

&<

D03

(from outside of the shaking table)

&;

&:

Anchor A-02

(Top) Anchor A-01

: Pressure

࿑ ┙㈩▤♽⹜㛎ޓ⸘᷹ὐ

Fig.2.2-8 Measurement points of the 3-D piping model.

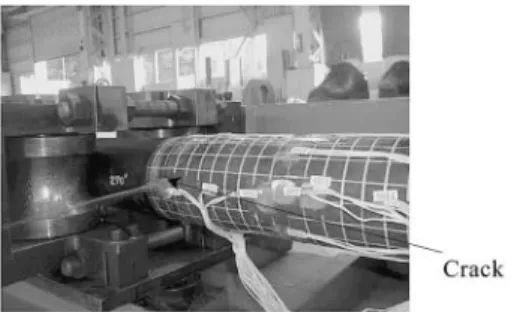

ታ㛎⚿ᨐ ⷐ⚛⹜㛎 ߈ⵚઃ߈㈩▤

⎕៊⁁ᴫ

ⷐ⚛⹜㛎ߩ߁ߜ߈ⵚઃ߈㈩▤ߩ⹜㛎⚿ᨐࠍߦ ߣࠅ߹ߣߡ␜ߔ㧚⹜㛎ߩ߁ߜᱜᒏᵄߦࠃࠅタ⩄ߒߚ

߽ߩߦߟߡߪ㧘߈ⵚ⽾ㅢ߹ߢߦⷐߒߚᱜᒏᵄቯᏱㇱಽ ߩᵄᢙࠍਛߦ૬⸥ߒߚ㧚ഠൻᒻ⁁ߏߣߩ⎕៊⁁ᴫߪએ ਅߩࠃ߁ߦߥߞߚ㧚

(1)ޓSCC⹜㛎

8ታᣉߒߚSCC⹜㛎ߩ߁ߜ㧘4ߢ➅ࠅߒ タ⩄ߦዉߒߚೋᦼSCC߆ࠄ∋ഭ߈ⵚ߇ㅴ ዷߒ㧘⽾ㅢߒߚ㧚߈ⵚ⽾ㅢㇱಽߦሽߒߚೋᦼ SCCᒻ⁁ߪ࿑ߦ␜ߒߚߣ߅ࠅߢࠆ㧚߈ⵚ

⽾ㅢᓟߩᓟ⛯ࠨࠗࠢ࡞ߦࠃࠆᣇะ߳ߩᕆㅦવ

ߪ↢ߓߥ߆ߞߚ㧚࿑ ߦ⹜㛎SC01ߩ

⎕៊⁁ᴫࠍ␜ߔ㧚ೋᦼSCC߆ࠄ߈ⵚ߇⽾ㅢߒߥ ߆ߞߚ4ߪ㧘⹜㛎㈩▤ࠍᒝ▤ߣធวߔࠆߚ

ߦടᎿߒߚṁធㇱಽ߿࠹ࡄ㐿ᆎㇱߢ߈ⵚ߇⽾

ㅢߒߚ㧚࿑ߦSCC⹜㛎ߩ⎕៊⟎ࠍ␜

ߔ㧚

(2)ޓో50%ᷓߐߩEDM߈ⵚઃ߈⹜㛎

㧔EM01㨪EM04㧕

ోߡߩ⹜㛎ߦ߅ߡ㧘ᦨᄢᦛߍࡕࡔࡦ࠻߇

↪ߔࠆᣇะߢ➅ࠅߒタ⩄ߦ߈ⵚ߇⡺ෘ

ᣇะߦㅴዷߒ㧘⽾ㅢߒߚ㧚⽾ㅢߒߚ߈ⵚߪᓟ⛯ߩ ᢙࠨࠗࠢ࡞ߦࠃࠅᣇะߦㅴዷߒ㧘ో⎕ᢿࠍ

ߎߒߚ㧚࿑ߦEM02ߩ⎕៊⁁ᴫࠍ␜ߔ㧚 ታ㛎ߢߪᱜᒏᵄߣࡦ࠳ࡓᝄᵄࠍ↪ߡタ⩄

ߒߚ߇㧘ജᵄᒻߦࠃࠆ⎕៊ᒻᘒߩ㆑ߪࠄ ࠇߥ߆ߞߚ㧚

(3)ޓౝⷺ90q50%ᷓߐߩEDM߈ⵚઃ߈⹜㛎

㧔EM05㧘EM09㧕

➅ࠅߒタ⩄ߦೋᦼEDM߈ⵚㇱಽ߆ࠄ߈ⵚ ߇ㅴዷߒ㧘⽾ㅢߒߚ㧚߈ⵚߪ⽾ㅢߩߺߢᓟ⛯ࠨࠗ

ࠢ࡞ߦࠃࠆᣇะ߳ߩᕆㅦવߪ↢ߓߥ߆ߞߚ㧚

(4)ޓSCCࠍᮨᡆߒߚEDM߈ⵚઃ߈⹜㛎

㧔EM06㨪EM08㧕

ోߡߩ⹜㛎ߢዉߒߚEDM߈ⵚㇱಽ߆ࠄ߈ⵚ ߇ㅴዷߒ㧘⽾ㅢߒߚ㧚SCC⹜㛎ߣห᭽㧘⎕៊ᒻ ᘒߪ߈ⵚߩ⽾ㅢ߅ࠃ߮ṳᵨߢ㧘ᓟ⛯ࠨࠗࠢ࡞ߦ ࠃࠆᣇะ߳ߩ߈ⵚߩᕆㅦવߪ↢ߓߥ߆ߞߚ㧚 એ߆ࠄ㧘ᧄታ㛎ߢ⏕ߐࠇߚ߈ⵚઃ߈㈩▤ߩ⎕៊ᒻᘒ ߪ㧘ㇱಽ߈ⵚઃ߈㈩▤ߢߪ߈ⵚߩ⽾ㅢ㧘ో߈ⵚઃ߈㈩▤

ߢߪో⎕ᢿߣߥߞߚ㧚

߈ⵚઃ߈㈩▤ߩ⩄㊀ᄌᒻ․ᕈ

࿑ߦEDM⹜㛎ߩᦨᄢജᄌᒻⷺߣᦛߍࡕ

ࡔࡦ࠻ߣߩ㑐ଥࠍ␜ߔ㧚ߚߛߒ㧘EM01ߪജࡌ࡞ࠍㅜ ਛߢᄌᦝߒߡࠆߩߢ㧘એਅߩᬌ⸛ߢߪኻ⽎ᄖߣߒߚ㧚࿑

ߢߪ㧘⹜㛎ߩᄌᒻߪోߡ߈ⵚㇱಽߢ߈ߡࠆߣߒߡ

࿑ ೋᦼSCC߈ⵚ߆ࠄߩ⽾ㅢ㧔SC01㧕 Fig. 3.1.1-1 Crack penetration from initial SCC (SC01).

Thicker wall pipe Test specimen SCC induced area

Broken position of

SC02 & SC04 Broken position of SC05 & SC06

Broken position of SC01, SC03,SC07 & SC08 (Broken from initial SCC)

13.5 8.6

࿑ ฦSCC⹜㛎ߩ߈ⵚ⽾ㅢ⟎

Fig. 3.1.1-2 Broken positions of SCC specimens.

࿑ ో⎕ᢿߩ⁁ᴫ

㧔EM02㧘ోEDM߈ⵚઃ߈⹜㛎㧕

0 10 20 30 40 50

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14

EM02 EM03 EM04 EM05 EM06 EM07 EM08 EM09

Bending moment [kN-m]

Rotation angle [rad]

Fig. 3.1.1-3 Full circumferential break

(EM02, with full circumferential initial EDM notch).

࿑ EDM⹜㛎ߦ߅ߌࠆᦨᄢജᄌᒻⷺߣ ᦨᄢᦛߍࡕࡔࡦ࠻ߩ㑐ଥ

Fig. 3.1.1-4 Relation between max. input rotation angle and max. bending moment of EDM specimen.

Input condition Max. amp. of input Name Type of defect

Internal pressure (P) [MPa]

Hoop stress byP (VH) [MPa] VH /SyPattern of input disp. wave [mm] [rad]

No. of loadingMax. reaction force [kN] Test results SC01 49 0.16 5 (108 cycles)96 Crack penetration at SCC SC02 49 0.16 21 83 Crack penetration at the tapering section SC03 49 0.16 5 (128 cycles)95 Crack penetration at SCC SC04 49 0.16 6 92 Crack penetration at the tapering section SC05 48 0.16 6 104 Crack penetration near the weld SC06 49 0.16 4 114 Crack penetration near the weld SC07 50 0.16 5 (127 cycles)92 Crack penetration at SCC SC08

SCC 8 49 0.16

Sinusoidal 50 0.13 5 (117 cycles) 93 Crack penetration at SCC 15 0.04 35 EM01 49 0.16 Random 30 0.08 2 71 Full circumferential break EM02 49 0.16 Sinusoidal 25 0.06 1 (16 cycles) 67 Full circumferential break EM03 49 0.16 Random25 0.06 10 69 Full circumferential break EM04 49 0.16 Sinusoidal 21 0.05 1 (18 cycles)66 Full circumferential break EM05 50 0.16 Random35 0.09 4 79 Crack penetration at EDM notch EM06 49 0.16 Sinusoidal 50 0.13 2 (32 cycles) 94Crack penetration at EDM notch EM07 48 0.16 Sinusoidal 50 0.13 3 (55 cycles) 108Crack penetration at EDM notch EM08 51 0.16 Sinusoidal 50 0.13 4 (108 cycles)90Crack penetration at EDM notch EM09

EDM 8 48 0.16 Sinusoidal 35 0.09 1 (19 cycles) 77Crack penetration at EDM notch

ⷐ⚛⹜㛎ޓ߈ⵚઃ߈㈩▤⹜㛎⹜㛎⚿ᨐ Table 3.1.1-1 Test results of pipe element tests using cracked specimens

ജᄌࠍ࿁ォⷺߦ㧘4ὐᦛߍ⹜㛎ⵝ⟎ߩᐞቇ⊛ᒻ⁁߆ࠄ

ജࠍᦛߍࡕࡔࡦ࠻ߦ឵▚ߒߡ␜ߒߚ㧚ߎߎߢ㧘ജᄌ

ࠍδ㧘4ὐᦛߍ⹜㛎ⵝ⟎ߩᡰὐ㑆〒㔌ࠍl㧘࿁ォⷺࠍφ㧘 ࡠ࠼࡞⸘᷹୯ࠍP㧘⹜㛎ߦ↪ߔࠆᦛߍࡕࡔࡦ࠻

ࠍMߣߔࠆߣ㧘φ㧘M㧘ߪߘࠇߙࠇએਅߩᑼߢߐࠇࠆ㧚 (3.1.1)

(3.1.2)

⹜㛎ߩജ߆ࠄ⸘▚ߒߚᦛߍࡕࡔࡦ࠻ߩᦨᄢ୯ߪ

ജߩᄢ߈ߐߦᔕߓߡ⚂25kN-m߆ࠄ40kN-mߩ▸࿐ߦಽ Ꮣߒߡࠆ㧚ࡦ࠳ࡓᝄᵄߢタ⩄ߒߚEM03ߣEM05ߪ㧘 ᱜᒏᵄߢタ⩄ߒߚEM02߅ࠃ߮EM09ߣ߶߷ห╬ߩജߣ ߥࠅ㧘ജᵄᒻߦࠃࠆജߩ㆑ߪࠄࠊࠇߥ߆ߞߚ㧚

࿑ߦ㧘ᱜᒏᵄタ⩄ࠍⴕߞߚEM02㧘EM06㧘EM09 ߦߟߡ㧘ᱜᒏᵄߩẋჇㇱಽߢߩ࿁ォⷺߣ⹜㛎ജߣ ߩ㑐ଥࠍ␜ߔ㧚EM02ߪో߈ⵚࠍ㧘EM06ߪSCCࠍᮨᡆ

ߒߚEDM߈ⵚࠍ㧘EM09ߪౝⷺ90qߩ⍱ᒻ߈ⵚࠍടᎿߒ

ߡࠆ߇㧘࿑߆ࠄ㧘ߎࠇࠄߩ߈ⵚߩᄢ߈ߐߪ⹜㛎

ߩജߦ߶ߣࠎߤᓇ㗀ࠍਈ߃ߡߥߣ⸒߃ࠆ㧚 5%% ߈ⵚߣ '&/ ߈ⵚߩ⎕៊ኼᲧセ

EDM⹜㛎EM06㧘EM07㧘EM08ߪ㧘ߘࠇߙࠇSCC⹜ 㛎SC01㧘SC03㧘SC07ߩೋᦼSCCᒻ⁁ࠍ╬ଔߥ߈ⵚᷓߐ ߣ㕙Ⓧࠍᜬߟඨᬦᒻ⁁ߢᮨᡆߒߚEDM߈ⵚࠍઃਈߒߚ

⹜㛎ߢࠆ㧚ߎࠇࠄߩ⹜㛎ߢߪ㧘⥄ὼ߈ⵚߣੱᎿᰳ㒱 ߩ⎕៊ኼߩᲧセࠍⴕ߁ߚߦ㧘ౝ㧘⹜㛎ߩ᧚⾰㧘

ജᄌ㧘ജᵄᒻߩ᧦ઙࠍห৻ߦߒߡタ⩄⹜㛎ࠍⴕߞߚ㧚 ߘߩ⚿ᨐ㧘߈ⵚ⽾ㅢߦⷐߒߚᱜᒏᵄߩቯᏱㇱಽߩࠨࠗࠢ

࡞ᢙߪ㧘SC01ߢ108ࠨࠗࠢ࡞㧘SC01ߩSCCࠍᮨᡆߒߚ EM06ߢ32ࠨࠗࠢ࡞ߢߞߚ㧚ห᭽ߦ㧘SC03ߢ128ࠨࠗ

ࠢ࡞㧘EM07ߢ55ࠨࠗࠢ࡞㧘SC07ߢ117ࠨࠗࠢ࡞㧘EM08 ߢ108ࠨࠗࠢ࡞ߣߥߞߚ㧚EM06ߣEM07ߢߪᮨᡆߒߚSCC ߦኻߒߡ߈ⵚ⽾ㅢ߹ߢߦ2㨪3ߩ➅ࠅߒᢙ߇ᔅⷐߛߞ

ߚߩߦኻߒ㧘EM08ߢߪ߶߷ห⒟ᐲߣߥߞߚ㧚ᤨὐߢߪ ߎߩ㆑߇↢ߓߚℂ↱ߪ⏕ߢߪߥ߇㧘❗タ⩄ᤨߦ ߅ߌࠆ߈ⵚ㕙ߩធ⸅ߦ߁❗߭ߕߺߩᣇߩ㆑߿㧘

ೋᦼSCCߩ┙⊛ᒻ⁁ߥߤ㧘߈ⵚᒻ⁁ࠍᮨᡆߔࠆ㓙ߦ⠨

ᘦߒߚᛩᓇ߈ⵚ㕙Ⓧએᄖߩⷐ࿃߇߈ⵚㅴዷߦᓇ㗀ࠍਈ߃ ߡࠆน⢻ᕈ߇⠨߃ࠄࠇࠆ㧚

⎕㕙⸃ᨆ

EDM⹜㛎ߩ߁ߜ㧘ోEDM߈ⵚઃ߈㈩▤ߢᱜᒏᵄ ࠍ↪ߡタ⩄ߒߚEM02㧘ࡦ࠳ࡓᝄᵄߢタ⩄ߒߚ

EM03㧘ౝⷺ90qߩ⍱ᒻEDM߈ⵚࠍᜬߜ㧘ࡦ࠳ࡓᝄ

ᵄߢタ⩄ߒߚEM05ߩ3ߦߟߡ㧘ᩏဳ㔚ሶ㗼ᓸ㏜

㧔SEM㧕ࠍ↪ߒߚ⎕㕙ⷰኤࠍⴕߞߚ㧚⎕㕙ߩⷰኤ⟎ߪ

࿑ ߦ␜ߒߚ⟎ߢࠆ㧚

ࡑࠢࡠ⊛ߥ⎕㕙ߪ㧘࿑ߦ␜ߒߚࠃ߁ߦ㧘タ⩄ߦ ࠃࠅ߈ⵚ߇ㅴዷߒߚㇱಽ㧔એਅㇱಽAߣߔࠆ㧕ߣᕆㅦ⎕

ᢿㇱಽ㧔એਅㇱಽBߣߔࠆ㧕ߦಽ߆ࠇߚ㧚ߎߩ߁ߜ㧘ࡦ

࠳ࡓᝄᵄߢタ⩄ߒߚ⹜㛎ߩㇱಽAࠍSEMߢⷰኤߔࠆ ߣ㧘࿑ߦ␜ߔࠃ߁ߦ❋ᮨ᭽߇ࠄࠇࠆ㗔ၞ㧔A- 1㧘ࠬ࠻࡚ࠗࠛࠪࡦ㗔ၞ㧕ߣ㧘߶ߣࠎߤ․ᓽߩࠇߥ

㗔ၞ㧔A-2㧘ࠬ࠻࠶࠴࠱ࡦ㗔ၞ㧕ߩ2⒳㘃ߩ⎕㕙߇

ߦࠇࠆߎߣ߇⏕ߐࠇߚ㧚࿑ Dߦ␜ߒߚ

ࡦ࠳ࡓᝄᵄߢタ⩄ߒߚ႐วߦ߈ⵚㅴዷㇱಽߢ2⒳㘃ߩ⎕

㕙߇ࠇࠆߩߪ㧘ᦨᄢᝄએᄖߩㇱಽߢA-1ߩ⎕㕙߇㧘ᦨ ᄢᝄㇱಽߢA-2ߩ⎕㕙߇ᒻᚑߐࠇࠆߚߣ⠨߃ࠄࠇࠆ㧚 ᓥߞߡ㧘A-1ߣA-2ߩ⎕㕙1⚵߇ࡦ࠳ࡓᝄᵄ1ᵄߦࠃ ࠆ߈ⵚㅴዷ㊂ߦ⋧ᒰߔࠆ㧚৻ᣇ㧘ᱜᒏᵄߢタ⩄ߒߚEM02 ߩSEMⷰኤ⚿ᨐߢߪA-1ߩࠃ߁ߥ⎕㕙ߪࠄࠇߕ㧘ో

ߡㇱಽA-2ߣห᭽ߩ⎕㕙ߢࠅ㧘SEMⷰኤ⚿ᨐ߆ࠄᔕജ ࠨࠗࠢ࡞Ფߩ߈ⵚㅴዷ㊂ࠍ․ቯߔࠆߎߣߪߢ߈ߥ߆ߞߚ㧚

0 5 10 15 20 25 30 35

0 0.02 0.04 0.06 0.08 0.1 0.12 0.14

EM 02 EM 06 EM 09

Bending moment [kN-m]

Rotation angle [rad]

࿑ ᱜᒏᵄߩᝄẋჇㇱߦ߅ߌࠆജᄌᒻⷺߣ ᦛߍࡕࡔࡦ࠻ߩ㑐ଥ

Fig. 3.1.1-5 Relation between input rotation angle and bending moment at amplitude increasing part of Sinusoidal input wave.

Loading direction

8.6 114.3 4.3

90q

Observation point (a) EM02 & EM03. (b) EM05.

࿑ ೋᦼEDM߈ⵚᒻ⁁ߣSEMⷰኤὐ

Fig. 3.1.1-6 Geometry of initial EDM notch and observation point by SEM.

࿑ ߈ⵚㅴዷ㕙ߩࡑࠢࡠ᭽⋧㧔EM03㧕 Fig. 3.1.1-7 View of crack surface (EM03).

Initial EDM notch Fatigue crack propagation

Dimple area 2

l φ = δ

2 M=P l⋅

ߦታ㛎⚿ᨐߣ㧘╙5┨ߢㅀߴࠆㅜታᣉߐࠇ ߚFEMߦࠃࠆ߈ⵚㅴዷ⸃ᨆ⚿ᨐߦࠃࠅᓧࠄࠇߚ߈ⵚ⽾ㅢ

߹ߢߩタ⩄࿁ᢙࠍ␜ߔ㧚⸃ᨆߢߪታ㛎⚿ᨐߣᲧセߒߡዋ ߥ➅ࠅߒᢙߢ߈ⵚ߇⽾ㅢߔࠆ⚿ᨐ߇ᓧࠄࠇߡࠆ㧚

৻ᣇ㧘ࡦ࠳ࡓᝄᵄߢタ⩄ߒߚ2ߦߟߡ㧘SEMⷰ ኤߦࠃࠆ߈ⵚㅴዷㇱಽߢ⏕ߐࠇߚ⎕㕙A-1ߣA-2ߩ⚵

ߪ㧘EM03ߢ10⚵㧘EM05ߢ4⚵ߣߥߞߚ㧚ㅀߩࠃ߁ߦ㧘

⎕㕙ߩ➅ࠅߒᢙߪ߈ⵚ⽾ㅢߦⷐߒߚࡦ࠳ࡓᝄᵄߩ タ⩄࿁ᢙߦ⋧ᒰߔࠆ㧚ᓥߞߡ㧘ታ㛎ߢ߈ⵚ⽾ㅢ߹ߢߦⷐߒ ߚ➅ࠅߒᢙߩ߁ߜ㧘߈ⵚ⊒↢ߦᶖ⾌ߐࠇߚ࿁ᢙߪήⷞ ߢ߈ࠆ⒟ᐲߢࠅ㧘߶ߣࠎߤߪ߈ⵚߩવߦ⾌߿ߐࠇߡ

ࠆߣ⠨߃ࠄࠇࠆ㧚

ᰴߦ㧘SEMⷰኤߢ⺒ߺߣߞߚࠬ࠻࡚ࠗࠛࠪࡦ㑆㓒 㧔S㧕߅ࠃ߮ࠬ࠻࠶࠴࠱ࡦ㧔SZW㧕ߣ㧘ታ㛎ߢᓧࠄࠇ ߚᔕജᄢଥᢙ▸࿐ࠍኻᔕߐߖ㧘da/dN - ∆K㑐ଥࠍ᳞

ߚ㧚ߥ߅㧘EM02ߦߟߡߪSEMⷰኤߦࠃࠆฦタ⩄ࠨࠗ

ࠢ࡞Ფߩ߈ⵚㅴዷ㊂ߩ․ቯߪߢ߈ߥ߆ߞߚ߇㧘ታ㗼ᓸ

㏜౮⌀ࠃࠅ⎕ᢿ೨2ࠨࠗࠢ࡞ಽߩ߈ⵚㅴዷ㊂ࠍ․ቯߢ߈ߚ ߚ㧘ߎߩ2ࠨࠗࠢ࡞ߦߟߡᔕജᝄߣ߈ⵚㅴዷ㊂ࠍኻ ᔕߐߖߚ㧚ߎߎߢ㧘ࠬ࠻࡚ࠗࠛࠪࡦ㗔ၞߢߪ㧘S߇⪺

ߒߊᄌൻߒߡߥᢙᵄߩᐔဋ୯ࠍda/dNߦ↪ߒ㧘ࠬ࠻

࠶࠴㗔ၞߢߪSZWࠍࡦ࠳ࡓᝄᵄߩᦨᄢᝄᵄߦ ࠃࠆda/dNߣߒߚ㧚߹ߚ㧘ᔕജᄢଥᢙ▸࿐∆Kߪਅᑼߢ

᳞ߚ㧚

ߎߎߢ㧘Fξ㧦K୯ߩᱜଥᢙޓ∆σ㧦↪ᔕജᝄޓ ޓޓޓޓa㧦߈ⵚ㐳ߐ

↪ᔕജᝄ∆σߪ㧘ᑼ3.1.2ߢᓧࠄࠇࠆജ߆ࠄ⸘▚

ߒߚࡕࡔࡦ࠻ࠍᢿ㕙ଥᢙZߢ㒰ߒߡ᳞ߚ㧚ߐࠄߦ㧘⎕

㕙ⷰኤ⟎ߦ߅ߌࠆᔕജ⁁ᘒࠍ㧘ㄭૃ⊛ߦ ߦ߈ⵚߩ

ࠆᏪ᧼ߩ৻᭽ᒁᒛ㧛❗ߣߒߡ⠨߃㧘ᔕജᝄߣ߈ⵚ 㐳ߐ߆ࠄᓧࠄࠇࠆ∆Kߦኻߒ㧘ᰴᑼߢਈ߃ࠄࠇࠆᱜଥᢙ ࠍਸ਼ߓߡ୯ࠍᱜߒߚ㧚

ߎߎߢ㧘ξ = a/W a㧦߈ⵚ㐳ߐ㧘W㧦᧼ෘ

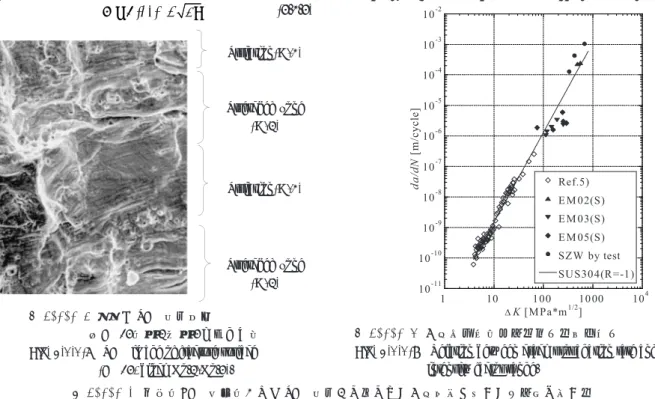

ⷰኤ⚿ᨐߣSasakiࠄߩ㜞ࠨࠗࠢ࡞∋ഭ⹜㛎⚿ᨐ5ࠍ࿑

ߦ␜ߔ㧚࿑ਛ㧘⊕ᛮ߈ߩ⪉ᒻ߇Sasakiࠄߦࠃࠆታ 㛎⚿ᨐ㧘Ⴃࠅߟ߱ߒߚὐ߇⎕㕙⸃ᨆ߆ࠄᓧࠄࠇߚda/dN -

∆K㑐ଥߢࠆ㧚ታ✢ߢ␜ߒߚ⋥✢ߪSasakiࠄߦࠃࠆታ㛎

⚿ᨐߩ߈ⵚવㅦᐲߩㄭૃᑼߢࠅ㧘ਅᑼߢߐࠇࠆ㧚ߎ ߎߢ㧘da/dNߪmm/cycle㧘∆KߪMPa㨯m1/2ߢࠆ㧚

(3.1.5)

࿑ߦ␜ߒߚࠃ߁ߦ㧘ᧄታ㛎ߢ⎕㕙⸃ᨆ߆ࠄᓧࠄ ࠇߚ߈ⵚવㅦᐲߪ㧘ᣢᓔߩ⎇ⓥߢᓧࠄࠇߡࠆda/dN -

∆K㑐ଥߣ⦟ߊ৻⥌ߒߚ㧚ᧄታ㛎ߢ↪ߒߚࡦ࠳ࡓᝄ

ᵄߩࠃ߁ߥᄌേᝄߩ⩄㊀߇↪ߔࠆ႐ว㧘߈ⵚㅴዷߦ

Striation(A-1)

Stretched zone (A-2)

Striation(A-1)

Stretched zone (A-2)

ታ㛎㧘FEM⸃ᨆ㧘߅ࠃ߮SEMⷰኤ߆ࠄᓧࠄࠇߚ߈ⵚ⽾ㅢߦⷐߒߚജ➅ࠅߒᢙ Table 3.1.1-2 Number of loading blocks obtained from tests, FEM analysis and SEM observation.

࿑ ⎕㕙ߩSEMⷰኤ⚿ᨐ 㧔EM03㧘╙2㨪╙3ࡉࡠ࠶ࠢ㧕 Fig. 3.1.1-8 SEM image of fracture surface (EM03, block No.2-No.3).

( ) K Fξ σ πa

∆ = ⋅ ∆ (3.1.3)

2 3 4

( ) 1.12 0.231 10.55 21.72 30.39

Fξ = − ξ+ ξ − ξ + ξ (3.1.4)

1.76 109

da K

dN

= ∗ − ⋅ ∆

10-11 10-10 10-9 10-8 10-7 10-6 10-5 10-4 10-3 10-2

1 10 100 10 00 104

Ref.5) E M 02(S) E M 03(S) E M 05(S) SZW by test SUS304(R=-1)

da/dN[m/cycle]

∆K[MPa*m1/2]

࿑ ߈ⵚㅴዷ㊂㧙ᔕജᄢଥᢙ▸࿐㑐ଥ

Fig. 3.1.1-9 Relation between crack propagation rate and stress intensity factor range.

* ‘t’ denotes the thickness at normal part ** Results from FEM analysis in Chapter 5

Condition of defect Loading times

Name

Type Full angle Depth*

Type of

loading Max. 'V

[MPa] Test results FEM** SEM

EM02 Sinusoidal 707 1

(16 cycles) 1

(8cycles) -- EM03

360q

Random 700 10 2 10

EM05 EDM

90q

0.5t

Random 820 4 2 4

* ‘t’ denotes the normal pipe thickness