㧝㧚ߪߓߦ

ㄭᐕ㧘ᯏ᪾ߩዊဳൻ㜞ᕈ⢻ൻߩߚߦ㧘ᡂ

⠻․ᕈߩᡷༀࠍ⋡⊛ߣߒߚ㕙ᡷ⾰ᛛⴚ߇ᯏ᭴ㇱຠߦ ኻߒߡᐢߊ↪ࠄࠇߡࠆ㧚ߘߩਛߢ߽DLC⤑ߪ㧘㜞

⎬ᐲ㧘ૐᡂଥᢙ㧘⠴⠻ᕈߦఝࠇࠆߥߤߩ㜞ᯏ⢻․

ᕈࠍߔࠆߎߣ߆ࠄ㧘ฦಽ㊁ߢᵈ⋡ࠍ㓸ߡࠆ㧚DLC

⤑ߪήẢṖਅߢఝࠇߚૐᡂࠍᓧࠄࠇࠆߎߣ߅ࠃ߮

⚛ࠍਥߣߒߡ᭴ᚑߐࠇࠆߎߣ߆ࠄ㧘ㄭᐕߩⅣႺߦఝߒ

᧚ᢱߣ߁ⷐ᳞ߣ৻⥌ߒߚߎߣ߽ᵈ⋡ߩⷐ࿃ߣߥߞ ߡࠆ㧚ߘߩߚ㧘DLC⤑ߩᏒ႐ߪᐕ㑆⚂20㧑ߩ

ߢჇടߒߡ߅ࠅ1)㧘᭽ޘߥಽ㊁ߢታ↪ൻ⎇ⓥ߇ㅴࠄࠇ ߡࠆ㧚

৻ᣇ㧘ࡊࠬ࠴࠶ࠢ᧚ᢱߪ㊄ዻ᧚ᢱߦᲧߴߡシ㊂㧘 ᤃᚑᒻᕈ㧘ૐ㛍㖸㧘ૐଔᩰ㧘⥄ᏆẢṖᕈߦఝࠇࠆߣ

ߞߚ․ᕈࠍߒߡࠆߎߣ߆ࠄ㧘ߒࠀ߁േㇱ᧚ߣߒߡ ᐢߊ↪ࠄࠇߡࠆ2)㧚ߒ߆ߒ㧘ࡊࠬ࠴࠶ࠢ᧚ᢱߪ

Mechanical Properties of DLC Coatings Prepared on PPS by RF Plasma CVD

Atsumu HONDA*, Morimasa NAKAMURA**, Takashi MATSUOKA***, and Tomoko HIRAYAMA****

(Received June 16, 2007)

In this paper, we report DLC coatings prepared on PPS (polyphenylene sulfide) substrate by RF plasma CVD technique. The substrate surface roughness was controlled to approximately Ra 0.1µm and four types of specimen were prepared under different RF power, from 100W to 400W. The coating thickness was controlled to 2.0µm. Structures and surface properties of the coatings were evaluated by raman spectroscopy, surface roughness test, surface observation using SEM, hardness test, and scratch test. Friction/wear properties were evaluated by ball-on-disk tribometer. SUS304, SUJ2, ZrO2 and Si3N4 ball were used as sliding partner of the friction test. After the friction test, friction coefficient and specific wear rate of each specimen were calculated. Surface roughness Ra decreased with RF power to 300W, however Ra of RF 400W DLC was higher than that of RF 300W because of number of cracks on RF 400W DLC. Dynamic hardness increased with RF power. Adhesiveness of RF 300W DLC was the best, however strength of adhesion seemed to be better than RF 300W DLC. Specific wear rates of RF300W and 400W DLC were found to be small in spite of ball material of sliding partner.

-G[YQTFUDLC, PPS, Surface morphology, Hardness, Adhesion, Tribological property

ࠠࡢ࠼&.%㧘225㧘㕙ᕈ⁁㧘⎬ߐ㧘ኒ⌕ᕈ㧘ᡂ⠻․ᕈ

4( ࡊ࠭ࡑ %8& ᴺࠍ↪ߡ 225 ߦᒻᚑߒߚ &.% ⤑ߩᯏ᪾⊛․ᕈ

ᧄᄙ ⛔㧘ਛᱜ㧘᧻ጟ ᢘ㧘ᐔጊሶ

*Graduate Student, Department of Mechanical Engineering, Graduate School, Doshisha University, Kyotanabe, Kyoto Telephone/ Fax :+81-774-65-6419

**Department of Mechanical Engineering, Graduate School, Doshisha University, Kyotanabe, Kyoto Telephone/ Fax :+81-774-65-6419, E-mail:etf1303@mail4.doshisha.ac.jp

***Department of Mechanical and Systems Engineering, Doshisha University, Kyoto Telephone/ Fax :+81-774-65-6414, E-mail:tmatsuok@mail.doshisha.ac.jp

**** Department of Energy and Mechanical Engineering, Doshisha University, Kyoto Telephone/ Fax :+81-774-65-6413, E-mail:thirayam@mail.doshisha.ac.jp

ᒝᐲ㧘ᕈ߇ૐߚߦ⠴ࠕࡉ࠶ࠪࡉᕈ߇ᒙ㧘

⎬⾰᧚ᢱࠍ⋧ᚻߦߒߚ႐ว㧘⠻߇ᕆỗߦㅴⴕߒ߿

ߔߥߤߩᰳὐࠍᜬߞߡࠆ3)㧚ߘߎߢ㧘ૐ⎬ᐲߥࡊ

ࠬ࠴࠶ࠢ᧚ᢱߦ DLC ⤑ࠍᒻᚑߒ㕙ࠍ㜞⎬ᐲൻߔ ࠆߎߣߦࠃࠅ㧘ࠕࡉ࠶ࠪࡉ⠻ࠍᛥߔࠆߣߣ߽ߦ

ᡂ․ᕈߩะ߇ᦼᓙߢ߈㧘ࡊࠬ࠴࠶ࠢ᧚ᢱߩ↪ㅜ

ᄢ߇น⢻ߣߥࠆ㧚ߒ߆ߒ㊄ዻ᧚ᢱߦᲧߴߡࡊࠬ࠴

࠶ࠢ᧚ᢱ߳ߩ DLC ⤑ᒻᚑߦ㑐ߔࠆ⎇ⓥႎ๔ߪ߹ࠅ ߥߐࠇߡߥ㧚㜞⎬ᐲߩDLC⤑ᒻᚑߦߪၮ᧼߳ߩࠗ

ࠝࡦⴣ᠄ߦࠃࠆౝㇱᔕജߩઃਈ߇ᔅⷐߣߐࠇߡ߅ࠅ4)㧘 ࡊࠬ࠴࠶ࠢ᧚ᢱߢߪ DLC ⤑ߩ⎬ߐ߇ૐน⢻ᕈ߇

ࠆ㧚ࡊࠬ࠴࠶ࠢ᧚ᢱߪ⚛ߦࠃࠅ᭴ᚑߐࠇߡࠆ ߚ DLC ⤑ߣߩኒ⌕ᕈߪᲧセ⊛⦟ߣ⠨߃ࠄࠇߡ

ࠆ߇3)㧘⠻ߩㅴⴕߦ࿃ߒߡDLC⤑߇㔌ߔࠆߣ࠻

ࠗࡏࡠࠫ․ᕈߩะߪㄟߥ㧚

ߘߎߢᧄ⎇ⓥߢߪ㧘ၮ᧼᧚ᢱߦࠬࡄࠛࡦࡊߩ

৻⒳ߢࠆ PPS㧔ࡐࡈࠚ࠾ࡦࠨ࡞ࡈࠔࠗ࠼㧕ࠍၮ

᧼ߦ↪㧘RFࡊ࠭ࡑCVDᴺߦࠃࠅ⇣ߥࠆRFജ ߢᒻᚑߒߚDLC⤑ߩᯏ᪾⊛․ᕈࠍ⺞ߴߚ㧚ౕ⊛ߦߪ㧘

⊹⤑ߩ㕙ᕈ⁁㧘⎬ߐ㧘ኒ⌕ᕈߣ࠻ࠗࡏࡠࠫ․ᕈ ߩⷰὐ߆ࠄ㧘PPSߦኻߔࠆDLC⤑ㆡ↪ߩലᕈࠍᬌ⸛

ߒߚ㧚

㧞㧚ታ㛎ᣇᴺ ⵍⷒᣇᴺ

DLC⤑ߩᒻᚑߦߪ㧘RFࡊ࠭ࡑCVDⵝ⟎㧔ࠨࡓࠦ

ࢃ PD-10M․㧕ࠍ↪ߚ㧚ⵝ⟎ߩ⇛࿑ࠍFig. 1ߦ

␜ߔ㧚ᧄⵝ⟎ߪᐔⴕᐔ᧼ဳߢࠅ㧘RF ᵄᢙߪ

13.56MHzߢ࡞ࡈࡃࠗࠕࠬᣇᑼߣߥߞߡࠆ㧚ၮ᧼ߦ

ߪPPS㧔࠹ࠢ࠻ࡠࡦPPS ᣣᧄࡐࡍࡦࠦࢃ㧕ࠍ↪

ߚ㧚PPS ၮ᧼ߪᒻ⁁Ǿ19×4mm ߢࠅ㧘㕙☻ߐߪ

⎇⏴ߦࠃࠅ▚ⴚᐔဋ☻ߐ㧔Ra㧕⚂0.1Pmߦ⺞ߒߚ㧚 ⵍⷒ᧦ઙߪ㧘ේᢱࠟࠬߦࡔ࠲ࡦ㧔CH4㧕ࠍ↪㧘ᵹ

㊂ࠍ30sccm㧘ജࠍ13Paߣߒ㧘RFജߪ100W㧘200W㧘 300W߅ࠃ߮400㨃ߣߒߚ㧚߹ߚ⤑ෘߪⵍⷒᤨ㑆ࠍᄌ߃ ࠆߎߣߢ㧘⚂2.0Pmߣߥࠆࠃ߁ᚑ⤑ߒߚ㧚㔚ᭂ㑆㓒ߪ 50mm㧘ၮ᧼ߪ㕖ടᾲߢⴕߞߚ㧚PPSၮ᧼ߪࠛ࠲ࡁ࡞

ਛߢ10ಽ㑆ߩ㖸ᵄᵞᵺ㧘ⵍⷒ⋥೨ߦⵝ⟎ౝߢ1ಽ㑆 ߩArࠟࠬߦࠃࠆࠗࠝࡦࡏࡦࡃ࠼ಣℂࠍᣉߒߚ㧚

㕙ᕈ⁁

ฦRFജߢᒻᚑߒߚDLC⤑㕙ࠍᩏ㔚ሶ㗼ᓸ㏜

㧔SEM㧘JSM5200ᣣᧄ㔚ሶࢃ㧕ߦࠃࠅⷰኤߒߚ㧚߹

ߚ㧘㕙ᒻ⁁᷹ቯⵝ⟎㧔Dektak 6M ࢃࠕ࡞ࡃ࠶ࠢ㧕 ࠍ↪ߡ㧘DLC⤑ᒻᚑߦࠃࠆၮ᧼ߩ㕙☻ߐߩᄌൻࠍ

⺞ߴߚ㧚

⎬ߐ᷹ቯ

RF ജߩ㆑ߦࠃࠆ⊹⤑⎬ߐߩᄌൻࠍ⺞ߴࠆߚ

ߦ㧘⎬ߐ⹜㛎ࠍⴕߞߚ㧚᷹ቯᯏེߦߪ㧘࠳ࠗ࠽ࡒ࠶ࠢ

ᓸዊ⎬ᐲ⸘㧔DUH-201 ࢃፉᵤᚲ㧕ࠍ↪ߚ㧚 ᧄ⹜㛎ᯏߢᓧࠄࠇࠆ࠳ࠗ࠽ࡒ࠶ࠢ⎬ߐDHߪ㧘ሶࠍ

⹜ᢱߦߒㄟㆊ⒟ߢߩ⩄㊀ߣߒㄟߺᷓߐ߆ࠄᓧࠄ ࠇࠆᧄ⹜㛎ᯏ⁛⥄ߩ⎬ߐߢࠅ㧘ਅᑼߦࠃߞߡ▚ߐ ࠇࠆ㧚

D2

P Į

DH 㧔1㧕

ߎߎߢ㧘P㧦⹜㛎⩄㊀㧔mN㧕㧘D㧦ߒㄟߺᷓߐ㧔Pm㧕㧘 ǩ㧦ሶᒻ⁁ߦࠃࠆቯᢙ㧔ᧄ⎇ⓥߢ↪ߚ 115qਃⷺ

㍙ሶߢߪǩ㧩3.8584㧕ߢࠆ㧚⹜㛎᧦ઙߪ㧘⹜㛎⩄

㊀1.0mN㧘⩄㊀⽶⩄ㅦᐲ 0.02844mN/s㧘ᜬᤨ㑆5sec ߣߒߚ㧚

ࠬࠢ࠶࠴⹜㛎

PPSၮ᧼ߣDLC⤑ߩኒ⌕ᕈࠍ⺞ߴࠆߚ㧘ᩏᒻࠬ

ࠢ࠶࠴࠹ࠬ࠲㧔SST-101 ࢃፉᵤᚲ㧕ࠍ↪ߡ

ࠬࠢ࠶࠴⹜㛎ࠍⴕߞߚ㧚⹜㛎ߦߪᦛ₸ඨᓘ15Pmߩ

࠳ࠗࡗࡕࡦ࠼ࠬ࠲ࠗࠬࠍ↪ߒ㧘⹜㛎᧦ઙߪሶ㒠 Fig. 1. Schematic diagram of RF plasma CVD apparatus.

CH4

Source gas Vacuum

RF generator pump MFC

Plasma

Substrate CH4

Source gas Vacuum

RF generator pump MFC

Plasma Plasma

Substrate

ਅㅦᐲ1Pm/s㧘ᝄ50Pm㧘ㅍࠅㅦᐲ20Pm/sߣߒߚ㧚 ኒ⌕ᕈߪDLC⤑߇㔌ߒߚ㓙ߩ⩄㊀㧔⥃⇇⩄㊀㧕ࠍ

᳞ࠆߎߣߢ⹏ଔߒߚ㧚ߥ߅㧘⥃⇇⩄㊀ࠍ᳞ࠆ㓙㧘

⊹⤑ߩ㔌ὐࠍቯߔࠆᔅⷐ߇ࠆߚ㧘⹜㛎ᤨߩࠬ

ࠢ࠶࠴〒㔌ߦኻߔࠆ㔚ᄌൻߣ⹜㛎ᓟߩࠬࠢ࠶࠴

∥ⷰኤߦࠃࠆ㔌⊒↢߹ߢߩࠬࠢ࠶࠴〒㔌ࠍᲧセߒ ߡቯߒߚ㧚ࠬࠢ࠶࠴∥ߩⷰኤߦߪ㧘శቇ㗼ᓸ㏜

㧔VH-8000 ࢃࠠࠛࡦࠬ㧕ࠍ↪ߚ㧚

ᡂ⠻⹜㛎

ࡏ࡞ࠝࡦ࠺ࠖࠬࠢဳᡂ⹜㛎ᯏ㧔FPR-2000 ࢃ

ࠬࠞ㧕ࠍ↪ߡᡂ⠻⹜㛎ࠍⴕߞߚ㧚࠺ࠖࠬ

ࠢߦฦRFജߢDLC⤑ࠍᒻᚑߒߚPPS⹜ᢱ㧘⋧ᚻ᧚ ߣߥࠆࡏ࡞㧔Ǿ4.8mm㧕ߦ18-8ࠬ࠹ࡦࠬ㧔SUS304㧕㧘 㜞⚛ࠢࡠࡓゲฃߌ㍑㧔SUJ2㧕㧘ࠫ࡞ࠦ࠾ࠕ㧔ZrO2㧕㧘

⓸ൻ⃯⚛㧔Si3N4㧕ࠍ↪ߒߚ㧚ฦࡏ࡞᧚ᢱߩ⎬ߐߪ SUS304㧘SUJ2㧘ZrO2㧘Si3N4ߩ㗅ߦࡆ࠶ࠞࠬ⎬ߐ㧔HV㧕 ߢߘࠇߙࠇ160㧘806㧘1312㧘1647ߢࠅ㧘࠳ࠗ࠽ࡒ࠶

ࠢ⎬ߐ(DH)ߢߪߘࠇߙࠇ260㧘1140㧘1512㧘2078ߢ

ߞߚ㧚⹜㛎᧦ઙߪ⩄㊀0.98N㧘࿁ォᢙ100rpm㧘᠁േඨ ᓘ3mm㧘ߔߴࠅ〒㔌678m(PPS)߅ࠃ߮1130m(DLC)㧘 ᄢ᳇ਛήẢṖߢࠆ㧚

ᡂଥᢙߪ㧘৻ቯߩု⋥⩄㊀ࠍਈ߃ߡࡏ࡞ࠍ⹜ᢱ ߦߒઃߌߚ⁁ᘒߢ㧘⹜ᢱࠍ৻ቯㅦᐲߢ࿁ォߐߖߚᤨ

ߩᡂജࠍ᷹ቯߒ㧘ᰴᑼࠍ↪ߡ▚ߒߚ㧚 N

µ F 㧔2㧕

ߎߎߢ㧘Ǵ㧦ᡂଥᢙ㧘F㧦ᡂജ0㧘N㧦ု⋥⩄㊀(N) ߢࠆ㧚

߹ߚ㧘ᡂ⹜㛎ᓟߩ⹜ᢱ߅ࠃ߮ࡏ࡞ߦ㑐ߒߡᲧ

⠻㊂(mm3/(Nm))ࠍ᷹ቯߒ㧘⠻․ᕈࠍ⹏ଔߒߚ㧚Ყ

⠻㊂ߪ㧘⠻Ⓧ(mm3)ࠍ⽶⩄⩄㊀(N)߅ࠃ߮᠁േ〒

㔌(m)ߢ㒰ߒߚ୯ߢࠆ㧚⹜ᢱ㧘ࡏ࡞ߘࠇߙࠇߩ⠻

∥ߩᢿ㕙ᒻ⁁⸘᷹ߦߪ㧘Dektak 6M㧘ᷓᐲᒻ⁁᷹ቯ㗼

ᓸ㏜㧔VK-8500 ࢃࠠࠛࡦࠬ㧕ࠍߘࠇߙࠇ↪ߚ㧚

⚿ᨐ߅ࠃ߮⠨ኤ 㕙ᕈ⁁

Fig. 2ߦ㧘ฦRFജߢᒻᚑߒߚDLC⤑ߩ㕙SEM

ࠍ␜ߔ㧚ᒻᚑߒߚDLC⤑ߪၮ᧼㕙ߣή㑐ଥߥಳಲ

ࠍߒߡ߅ࠅ㧘RFജߩჇᄢߦߞߡ⊹⤑߇✺ኒൻߒ ߡࠆࠃ߁ߦ߃ࠆ㧚⊹⤑ߩಳಲߪ⊹⤑ߩᚑ㐳ㆊ⒟ߦ

࿃ߒߡࠆߣ⠨߃ࠄࠇ㧘ᩭߩᒻᚑߣፉ⁁ߩᚑ㐳ᒻᘒ ࠍߣߞߡDLC⤑߇ᒻᚑߐࠇߚߎߣߦࠃࠆߣᕁࠊࠇࠆ㧚

߹ߚ㧘RF100WߢߩDLC⤑ߪ㧘ಳಲ߇ᄢ߈ߊߥߞߡ

ࠆࠃ߁ߦฃߌࠄࠇࠆ㧚DLC⤑ߪㆊᐲߥ᳓⚛ᷝടߦࠃ ࠅࡐࡑൻߔࠆߎߣ5)߇⍮ࠄࠇߡ߅ࠅ㧘ߘߒߡࠕࡕ࡞

ࡈࠔࠬ⚛⤑ߪ㤥⦡ߢࠆߩߦኻߒ㧘㜞ಽሶ♽ߩ⚛

⤑⨥ⶊ⦡ߢࠆߣߩႎ๔߇ࠆ6)㧚ᧄ⺰ᢥߢ↪ߚDLC

⤑ߪ㧘RF200W એߢߪ㤥⦡ࠍ๒ߒߡߚߩߦኻߒ

RF100W ߢߪ⨥ⶊ⦡ߢߞߚ㧚߹ߚ㧘ࡑࡦࠬࡍࠢ࠻

࡞ߩࡌࠬࠗࡦߩ߈߇ዊߐߣ⊹⤑ਛߩ᳓⚛Ớᐲ ߇ૐߣߩႎ๔߇ߥߐࠇߡࠆߎߣ߆ࠄ7)㧘ฦRFജ ߢᒻᚑߒߚDLC⤑ߦࡑࡦಽశಽᨆࠍⴕ㧘ࡑࡦࠬ

ࡍࠢ࠻࡞ߩࡌࠬࠗࡦߩ߈ࠍᲧセߒߚ㧚Fig. 3ߦ㧘

RF100W ߩࡌࠬࠗࡦߩ߈ࠍၮḰߣߒߡ㧘ฦ RF

ജߩ߈ߣߩᲧࠍ␜ߔ㧚ߎߩ⚿ᨐࠃࠅRF100Wߪઁ

ߩ RF ജߦᲧߴߡࡌࠬࠗࡦߩ߈߇㕖Ᏹߦᄢ߈

Fig. 2. SEM images of DLC coatings on each RF power.

Fig. 3. Relative gradient of the baseline of Raman spectra on each RF power.

10㱘m RF100W

10㱘m

10㱘m

10㱘m

RF300W RF400W

RF200W

10㱘m RF100W

10㱘m

10㱘m

10㱘m

RF300W RF400W

RF200W

0 0.5 1 1.5

0 100 200 300 400 500 RF power [W]

Relative gradient of baseline

0 0.5 1 1.5

0 100 200 300 400 500 RF power [W]

Relative gradient of baseline

ߊ㧘⊹⤑ਛߩ᳓⚛Ớᐲ߇㜞ߣᕁࠊࠇࠆ㧚ߎࠇࠄߩ⚿

ᨐ߆ࠄ㧘RF100WߢᒻᚑߒߚDLC⤑ߪࡐࡑ⁁ߩ⊹

⤑ߢߞߚߣផ᷹ߐࠇ㧘ߘߩߚ⊹⤑㕙ߩಳಲ߇ᄢ ߈ߊߥߞߚߣ⠨߃ࠄࠇࠆ㧚

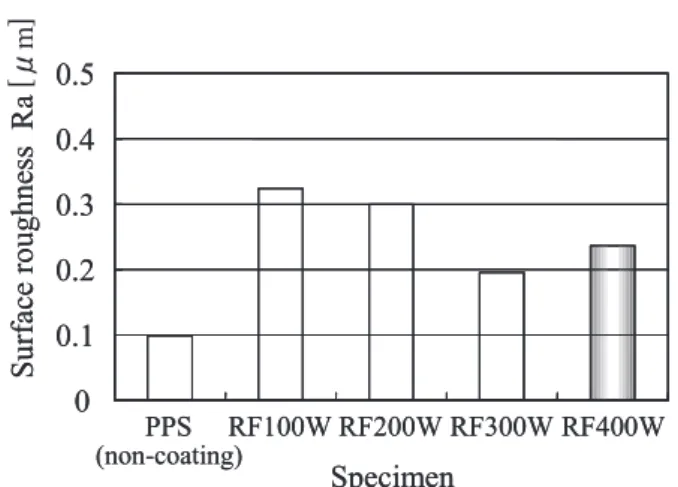

Fig. 4ߦ㧘DLC⤑ߩ㕙☻ߐࠍ᷹ቯߒߚ⚿ᨐࠍ␜ߔ㧚 DLC⤑ࠍᒻᚑߔࠆߣPPSၮ᧼ߩ㕙☻ߐࠃࠅ⊹⤑ߩ

㕙☻ߐ߇Ⴧᄢߒߚ㧚ߘߒߡ㧘RF300W߹ߢߪRFജߩ ߩߎߣߪ㧘Fig. 2ߢ߽⏕ߒߚ߇㧘RFജߩჇᄢߦ

⊹⤑߇✺ኒൻߒߡࠆߎߣ߇ⷐ࿃ߣ⠨߃ࠄࠇࠆ㧚ߒ

߆ߒ㧘RF400W ߢ⊹⤑ߪᦨ߽✺ኒൻߒߡߚߦ߽㑐ࠄ

ߕ㧘㕙☻ߐߪRF300Wࠃࠅ߽Ⴧᄢߔࠆ⚿ᨐࠍ␜ߒߚ㧚

ߘߎߢ㧘RF300W㧘400WߩDLC⤑ߩߺ⊹⤑㕙ࠍFig.

2ࠃࠅ߽ૐ₸ߢⷰኤߒߚ㧚Fig. 5ߦߘߩ⚿ᨐࠍ␜ߔ㧚

RF300W ߢߪ⊹⤑㕙ߦᄢ߈ߥഀࠇߪࠄࠇߥ߇㧘

RF400W ߢߪᄙᢙߩഀࠇ߇ࠄࠇࠆ㧚RF400Wߩ⊹

⤑㕙ߩഀࠇߪ㧘ᚑ⤑᷷ᐲߣࠗࠝࡦⴣ⓭ߩᒝߐߦ࿃

ߒߡࠆߣ⠨߃ࠄࠇࠆ㧚㜞ᚑ⤑᷷ᐲ߿ᒝࠗࠝࡦⴣ

⓭ߪ㧘⊹⤑ߦ㜞ౝㇱᔕജࠍౝߔࠆⷐ࿃ߣߥࠆ㧚

RF400W ߢߪ㧘㜞ౝㇱᔕജߦ࿃ߒߡ⊹⤑㕙ߦഀ

ࠇ߇↢ߓߚߣ⠨߃ࠄࠇࠆ㧚

⊹⤑⎬ߐ

Fig. 6ߦ㧘⎬ߐ⹜㛎⚿ᨐࠍ␜ߔ㧚PPSၮ᧼ߦDLC

⤑ࠍᒻᚑߔࠆߎߣߢ㧘PPSߦᲧߴ⎬ߐ߇8㨪15⒟ᐲ

ߒߡࠆߎߣ߇ࠊ߆ࠆ㧚ߘߒߡ㧘RFജߩჇടߦ

⎬ߐߪߔࠆะࠍ␜ߒߡࠆ㧚ౝㇱᔕജߩჇ ᄢߣ⎬ߐߩߩ⋧㑐߇৻⥸⊛ߦ⍮ࠄࠇߡࠆߎߣ߆ ࠄ㧘RFജߩჇടߦ߁ౝㇱᔕജߩჇᄢ߇ⷐ࿃ߩ৻ߟ ߣߒߡ⠨߃ࠄࠇࠆ㧚RFജߩჇടߪၮ᧼߳ߩࠗࠝࡦߩ ⴣ⓭ㅦᐲߩࠍᒁ߈ߎߔߚ㧘DLC⤑ߦ㜞ౝㇱ ᔕജࠍౝߐߖߚߣផ᷹ߐࠇࠆ㧚߹ߚ㧘⊹⤑ਛߩ᳓⚛

Ớᐲ߇ૐ߶ߤ DLC ⤑ߩ⎬ߐ߇ߔࠆߎߣ߇ႎ๔ ߐࠇߡࠆ8)㧚ᧄ⎇ⓥߦ߅ߡ߽㧘ࡑࡦಽశಽᨆߩ⚿

ᨐࠃࠅ RF ജߩჇടߦ߁⊹⤑ਛߩ᳓⚛Ớᐲߩૐਅ ߇⏕ߐࠇߡࠆߎߣ߆ࠄ㧘RFജߩჇടߦ߁⎬ߐ ߩߪ㧘᳓⚛Ớᐲߩૐਅ߽࿃ߒߡࠆߣᕁࠊࠇࠆ㧚

ኒ⌕ᕈ

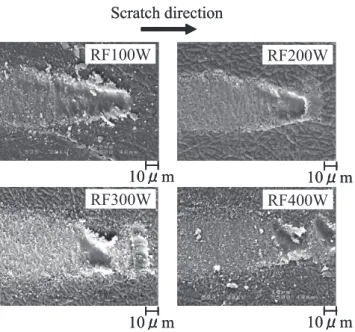

Fig㧚7ߦ㧘ࠬࠢ࠶࠴⹜㛎ߩ⚿ᨐࠍ␜ߔ㧚ߘߒߡ㧘 Fig. 8ߦࠬࠢ࠶࠴∥ߩSEMࠍ␜ߔ㧚RFജ߇300W

߹ߢߪ RF ജߩჇടߣߣ߽ߦኒ⌕ᕈ߇ะߒ㧘 RF400Wߩኒ⌕ᕈߪRF300Wߣᄢ߈ߊᄌൻߒߡߥ㧚 RFജߩჇടߣߣ߽ߦኒ⌕ᕈ߇ะߔࠆߩߪ㧘ࠗࠝࡦ ߩⴣ⓭ㅦᐲߦࠃࠆၮ᧼ߣDLC⤑ߩઃ⌕ജߩჇᄢ㧘 ߅ࠃ߮⊹⤑⎬ᐲ߇ⷐ࿃ߣ⠨߃ࠄࠇࠆ㧚Fig. 8ߦ߅

ߡRFജߩჇടߦDLC⤑ߩ㔌ὐ߇⏕ߦࠇ ߡ߅ࠅ㧘ߎߩߎߣߦߪઃ⌕ജߩჇᄢߣ⊹⤑⎬ߐߩ

߇ᄢ߈ߊᓇ㗀ߒߡࠆߣ⠨߃ࠄࠇࠆ㧚

㔌ὐߢߪ⊹⤑ߩઃ⌕ജߩჇᄢߦߞߡPPSၮ᧼߇

ᷓߊࠅขࠄࠇߡࠆ᭽ሶ߇ࠄࠇߚߎߣ߆ࠄ㧘㔌 ὐ೨ᓟߢၮ᧼ߩᢿ㕙ᒻ⁁ࠍ⺞ߴߚ㧚Fig. 9ߦߘߩ⚿ᨐࠍ Fig. 6. Dynamic hardness of DLC coatings on each RF

power.

Fig. 4. Surface roughness of DLC coatings deposited by each RF power.

Fig. 5. SEM images of DLC coatings on two types of RF power.

(non-coating)PPS RF100W RF200W RF300W RF400W 0

200 400 600 800 1000

Specimen

Dynamic hardness DH

(non-coating)PPS RF100W RF200W RF300W RF400W 0

200 400 600 800 1000

Specimen

Dynamic hardness DH

100

㱘

m 100㱘

mRF300W RF400W

100

㱘

m 100㱘

mRF300W RF400W

0 0.1 0.2 0.3 0.4 0.5

PPS RF100W RF200W RF300W RF400W Specimen

Surface roughness Ra

(non-coating) 0

0.1 0.2 0.3 0.4 0.5

PPS RF100W RF200W RF300W RF400W Specimen

Surface roughness Ra

(non-coating)

[㱘m]

␜ߔ㧚RF100Wߢߪ⊹⤑⎬ᐲߣઃ⌕ജ߇ૐߚ㧘DLC

⤑߇ࠅขࠄࠇPPSၮ᧼߇ᓢޘߦࠇߡࠆ᭽ሶ߇⏕

ߢ߈ࠆߩߦኻߒ㧘RF200W㨪400Wߢߪ㔌ὐߢᄢ߈ ߊᒻ⁁߇ᄌൻߒߡ߅ࠅ㧘DLC⤑ߣߣ߽ߦPPSၮ᧼߇৻

᳇ߦ⎕უߒߡࠆࠃ߁ߦ߃ࠆ㧚߹ߚ㧘RF200W㨪400W ߢߪRFജߩჇടߦPPSၮ᧼ߩ⎕უ߇ᕆỗߦߥ ࠆࠃ߁ߦฃߌࠄࠇࠆߎߣ߆ࠄ㧘RFജߩჇടߦ

ၮ᧼ߣDLC⤑ߩઃ⌕ജ߇Ⴧᄢߒߡߚߣ⠨߃ࠄࠇࠆ㧚 ߚߛ㧘RF300Wࠃࠅ߽400Wߢ⥃⇇⩄㊀߇Ⴧᄢߒߥ߆ ߞߚߩߪ㧘ᚑ⤑᷷ᐲ߇࿃ߒߡࠆߣ⠨߃ࠄࠇࠆ㧚㜞 ಽሶ᧚ᢱߢࠆPPSߪ✢⤘ᒛଥᢙ߇Ყセ⊛㜞ߚߦ ⵍⷒᤨߩ᷷ᐲߩᓇ㗀ࠍฃߌ߿ߔߊ㧘ⵍⷒᓟߩ಄ළᤨߦ PPSၮ᧼ߣDLC⤑ߣߩ✢⤘ᒛଥᢙߩᏅߦࠃߞߡ⇇㕙ߦ ߖࠎᢿജ߇↢ߓࠆ㧚RFജߩჇടߦ߁ᚑ⤑᷷ᐲߩჇ ᄢߦࠃߞߡߖࠎᢿജ߇Ⴧᄢߒ㧘⇇㕙ߢߩઃ⌕ജࠍ߃ ࠆߣ㔌߇↢ߓࠆ㧚Fig. 5ߢ㧘RF300Wߢߪࠄࠇߥ

ㇱಽ⊛ߥ㔌߇ RF400W ߦߪ↢ߓߡߚߎߣ߆ࠄ㧘

RF400W ߢߪ⇇㕙ㄭறߦ㜞ߖࠎᢿജ߇ሽߒߡ߅ࠅ㧘

ᄖജߦࠃࠅ㔌ߒ߿ߔ⁁ᘒߦߥߞߡߚߣផ᷹ߐࠇ ࠆ㧚ߒߚ߇ߞߡ㧘RF400WߢᒻᚑߔࠆߣPPSၮ᧼ߣDLC

⤑ߩઃ⌕ജߪᦨ߽㜞ߪߕߢࠆ߇㧘ၮ᧼ߣDLC⤑ߩ

⇇㕙ߦᓸዊߥ㔌߿㜞ߖࠎᢿജ߇ሽߒߡߚߚ㧘

RF300W ߦᲧߴߡኒ⌕ᕈ߇ะߒߥ߆ߞߚߣᕁࠊࠇࠆ㧚

࠻ࠗࡏࡠࠫ․ᕈ ᡂ․ᕈ

Fig. 10ߦ㧘ቯᏱ⁁ᘒߢߩᐔဋᡂଥᢙࠍ␜ߔ㧚ߥ߅㧘

Fig. 10ߦ߅ߌࠆࠣࡈߩࠛࡃߪ㧘ᡂଥᢙ

ߩᄌേࠍ␜ߒߡࠆ㧚RF100W㧘200W ߦ߅ߌࠆ SUS304ࡏ࡞ߣSUJ2ࡏ࡞ࠍ↪ߚ႐วߦߪ㧘DLC

⤑ߩ㔌ߦࠃࠅPPSߣห⒟ᐲ߹ߢᡂଥᢙ߇㜞ߊߥߞ ߡࠆ㧚ߒ߆ߒ㧘DLC⤑߇㔌ߒߥ႐วߦߪ㧘ߤߩ ࡏ࡞ࠍ↪ߚ႐วߢ߽PPSߦᲧߴᡂଥᢙߪᄢ߈ߊ

ᷫዋߒߡࠆ㧚ߐࠄߦ㧘ᡂଥᢙߩᄌേ߽ዊߐߊߥ ࠅ㧘ᡂേ߇ቯߒߡࠆߎߣ߇ࠊ߆ࠆ㧚ฦࡏ࡞

ࠍᡂ⋧ᚻ᧚ߣߒߚᡂଥᢙߩૐਅ₸ߪSUS304ߢ⚂

50㧑㧘SUJ2ߢ⚂35㧑㧘ZrO2ߢ40㨪60㧑㧘Si3N4ߢ50 㨪65㧑ߢࠅ㧘ૐਅ₸ߣࡏ࡞ߩ⎬ߐߦ⋧㑐ߪࠄ ࠇߥ߆ߞߚ㧚ߣߎࠈߢ㧘Fig. 10ߦ߅ߡ㧘ࡏ࡞߇㊄ ዻ᧚ᢱߩ႐วࠃࠅ߽ࡒ࠶ࠢ᧚ᢱߩ႐วߩᣇ߇㧘

ᡂଥᢙ߇ૐ㧚㊄ዻ᧚ᢱࠍࡏ࡞ߦ↪ߚ႐วߢߪ㧘 RF100W㧘200W ߩDLC ⤑ߪ㔌ߒߚ߇㧘RF300W㧘 Fig. 7. Critical load of DLC coatings on scratch test as a

function of RF power.

Fig. 8. SEM images of scratch tracks on DLC coatings deposited by different RF power.

Fig. 9. Surface profiles in the vicinity of the flaking point of the scratch track on DLC coatings.

10

㱘

m10

㱘

m10

㱘

m10

㱘

m Scratch directionRF100W RF200W

RF300W RF400W

10

㱘

m10

㱘

m10

㱘

m10

㱘

m Scratch directionRF100W RF200W

RF300W RF400W

-10 0 10

Profile [㱘m]

0 100

RF100W

0 100

RF200W

-10 0 10

Profile [㱘m]

0 100

Distance [㱘m]

RF300W

0 100

Distance [㱘m]

RF400W Sliding distance

-10 0 10

Profile [㱘m]

0 100

RF100W

0 100

RF200W

-10 0 10

Profile [㱘m]

0 100

Distance [㱘m]

RF300W

0 100

Distance [㱘m]

RF400W Sliding distance 0

10 20 30 40 50 60

100 200 300 400

RF power [W]

Critical load [mN]

0 10 20 30 40 50 60

100 200 300 400

RF power [W]

Critical load [mN]

400WߩDLC⤑ߪ㔌ߖߕ㧘ࡏ࡞᧚ᢱߦࠃࠅᡂଥ ᢙߦᏅ߇ࠄࠇࠆ㧚৻ᣇ㧘ࡒ࠶ࠢ᧚ᢱࠍࡏ࡞ߦ

↪ߚ႐วߢߪ㧘ߕࠇߩRFജߩDLC⤑߽㔌ߒ ߥ߆ߞߚ㧘ࡏ࡞᧚ᢱߩ㆑ߦࠃࠆᡂଥᢙߩᄌൻ ߪ㧘㊄ዻ᧚ᢱߩ႐วߣᲧセߒߡ߶ߣࠎߤߥ߆ߞߚ㧚ߒ ߚ߇ߞߡ㧘ࡏ࡞߇㊄ዻ᧚ᢱߣࡒ࠶ࠢ᧚ᢱߩᡂ

․ᕈߩ㆑ߪ㧘ࡏ࡞ߩ᧚ᢱ․ᕈ߿ᡂ⁁ᘒߩ㆑ߦ ࠃࠆ߽ߩߣ⠨߃ࠄࠇࠆ㧚߹ߚ㧘ࡏ࡞߇㊄ዻ᧚ᢱߩ႐ วߦߪ㧘RF300W㧘400Wߢߪࡏ࡞ߩ⠻∥ߦ⒖⌕⤑

߇ᒻᚑߐࠇߡߚ㧚 RF100W㧘200W ߢߪ⒖⌕⤑ߩᒻ ᚑߪࠄࠇߥ߆ߞߚ㧚ߎߩߎߣߪ㧘ࡏ࡞߇㊄ዻ᧚ ᢱߩ႐วߪ㜞ಝ⌕ᕈߦࠃࠅ DLC ⤑ߩ⠻߇↢ߓ߿

ߔ⁁ᘒߦࠆ߇㧘⒖⌕⤑߇ᒻᚑߐࠇࠆߣ⦟ᅢߥᡂ

․ᕈ߇ᓧࠄࠇࠆߎߣࠍ␜ໂߔࠆ߽ߩߣ⸒߃ࠆ㧚⒖⌕⤑

ᒻᚑࡔࠞ࠾࠭ࡓߩ⸃ߪᲑ㓏ߢߪ࿎㔍ߢࠆ߇㧘 DLC⤑ߩ⎬ߐ߇㜞ߎߣ߅ࠃ߮Sp2⚿วࠞࡏࡦߩሽ

₸ߦ࿃ߒߡࠆߩߢߪߥ߆ߣ⠨߃ߡࠆ㧚

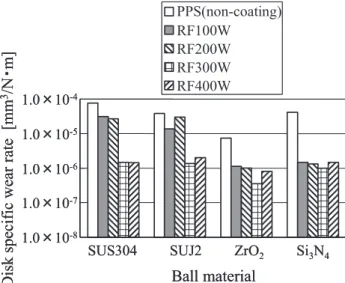

⠻․ᕈ

Fig. 11ߦ㧘ฦࡏ࡞ࠍ↪ߚᡂ⹜㛎ᓟߩ⹜ᢱߩᲧ

⠻㊂ࠍ␜ߔ㧚 DLC⤑߇㔌ߒߥ㒢ࠅߪฦRFജ ߢᚑ⤑ߒߚ⹜ᢱߩᲧ⠻㊂߇PPSߩ⚂1/10㨪1/50ߦ ૐᷫߒߡࠆ㧚ߎߩⷐ࿃ߪ㧘DLC⤑ࠍᒻᚑߔࠆߎߣߦ ࠃࠅ⹜ᢱ㕙ߩ⎬ߐ߇ᄢߦะߒߚߎߣ㧘߅ࠃ߮ૐ

ᡂ․ᕈ߇ᓧࠄࠇߚߎߣߢࠆߣ⠨߃ࠄࠇࠆ㧚RFജ ߩ㆑ߦࠃࠆᲧ⠻㊂ࠍᲧセߔࠆߣ㧘SUS304ࠍ㒰ߡ

ߕࠇߩࡏ࡞ࠍ↪ߚ႐วߢ߽RF300Wߩ⹜ᢱߢᦨ

߽Ყ⠻㊂߇ዊߐะ߇ࠄࠇࠆ㧚ߎࠇߪ㧘

RF300W ߩ⹜ᢱߩ㕙☻ߐ߇ᦨ߽ዊߐ߆ߞߚߚ㧘ೋ

ᦼ⠻߇ዋߥ⁁ᘒߢᡂ㕙߇ቯߒߚߎߣ㧘߅ࠃ߮

ኒ⌕ᕈ߇ᦨ߽㜞߆ߞߚߎߣ߇ⷐ࿃ߣ⠨߃ࠄࠇࠆ㧚ߎߎ ߢ㧘ࡏ࡞߇SUS304ߩ႐วߦᲧ⠻㊂߇RF300Wߢ ᦨ߽ዊߐߊߥࠄߥ߆ߞߚߎߣߦߟߡ⠨߃ࠆ㧚RF400W ߢᒻᚑߒߚDLC⤑ߩ⎬ߐߪᦨ߽㜞߆ߞߚ߇㧘⊹⤑⎬ߐ ߩߪࡏ࡞ߩ⠻ࠍჇᄢߐߖࠆⷐ࿃ߦ߽ߥࠅ㧘㜞

⎬ᐲߩࡏ࡞ߩ⠻☳ߪࠕࡉ࠶ࠪࡉ⠻ࠍᒁ߈ߎ ߒߚߣ⠨߃ࠄࠇࠆ㧚SUS304ߪૐ⎬ᐲߩߚ⠻☳߇ࠕ ࡉ࠶ࠪࡉ⠻ߩⷐ࿃ߣߪߥࠄߕ㧘RF400W ߢߪ⹜ᢱ ߩ⠻㊂߇Ⴧടߔࠆะࠍ␜ߐߥ߆ߞߚߣᕁࠊࠇࠆ㧚

ᰴߦ㧘ࡏ࡞ߏߣߦ⹜ᢱߩᲧ⠻㊂ࠍᲧセߔࠆߣ㧘 DLC⤑߇㔌ߒߚRF100W㧘200Wߩ⹜ᢱߦ㊄ዻ᧚ᢱ ߩࡏ࡞ࠍ↪ߚ႐วߣ㧘ࡏ࡞ߦZrO2ࠍ↪ߚ႐ว ࠍ㒰ߡߪ㧘Ყ⠻㊂ߪ߶ߣࠎߤᄌൻߒߡߥ㧚৻

ᣇ㧘RF300W㧘400Wߩ⊹⤑ߦࡒ࠶ࠢ᧚ᢱߩࡏ࡞

ࠍ↪ߚ႐วߢߪ㧘ᡂ․ᕈߦ߶ߣࠎߤᄌൻ߇ߥ߆ߞ ߚߦ߽㑐ࠊࠄߕ㧘Ყ⠻㊂ߦߪᏅ߇↢ߓߡࠆ㧚ZrO2

ߣSi3N4ߦ߅ߌࠆᲧ⠻㊂ߩᏅߪ㧘⠻☳ߦࠃࠆࠕࡉ

࠶ࠪࡉ⠻ߦ࿃ߒߡࠆߣ⠨߃ࠄࠇࠆ߇㧘SUS304 ߣ SUJ2 ߦ߅ߌࠆᲧ⠻㊂ߩᏅߪࡏ࡞ߩ⠻ߩㅴⴕ ㅦᐲߦ࿃ߒߡࠆߣ⠨߃ࠄࠇࠆ㧚ቯᏱ⁁ᘒߦ㆐ߒߚ 㓙ߦࡏ࡞ߩ⠻㊂ߪ߶߷ห⒟ᐲߢߞߡ߽㧘SUS304 ߇ૐ⎬ᐲߢࠆߚࡏ࡞ߩ⠻㊂ߪᡂೋᦼ߆ࠄᄢ ߈ߊߥߞߡࠆߣ⠨߃ࠄࠇࠆ㧚ߒߚ߇ߞߡ㧘SUS304 ߪ SUJ2 ࠃࠅ߽ᄢ߈ߥ㕙Ⓧߢធ⸅ߒߡ⹜ᢱࠍ⠻ߐߖ

Fig. 10. Friction coefficient of each specimen with four

types of ball material as reached by steady-state friction. Fig. 11. Specific wear rate of each specimen with four types of ball material.

SUS304 SUJ2 ZrO2 Si3N4 Ball material

Disk specific wear rate [mm3/N

䊶

m]PPS(non-coating) RF100W

RF200W RF300W RF400W

1.0㬍10-6 1.0㬍10-4 1.0㬍10-5

1.0㬍10-7 1.0㬍10-8

SUS304 SUJ2 ZrO2 Si3N4 Ball material

Disk specific wear rate [mm3/N

䊶

m]PPS(non-coating) RF100W

RF200W RF300W RF400W

1.0㬍10-6 1.0㬍10-4 1.0㬍10-5

1.0㬍10-7 1.0㬍10-8 0

0.1 0.2 0.3 0.4 0.5

SUS304 SUJ2 ZrO2 Si3N4 Ball material

Friction coefficient

㱘

PPS(non-coating) RF100W RF200W RF300W RF400W

0 0.1 0.2 0.3 0.4 0.5

SUS304 SUJ2 ZrO2 Si3N4 Ball material

Friction coefficient

㱘

PPS(non-coating) RF100W RF200W RF300W RF400W PPS(non-coating) RF100W RF200W RF300W RF400W

ߡߚߣផ᷹ߢ߈ࠆ㧚ࠃߞߡ⹜ᢱߩ⠻ߩㅴⴕㅦᐲ ߦ߽Ꮕ߇↢ߓ㧘RF300W ߦ߅ߡ⹜㛎⚳ੌᤨߦߪ SUS304ߣSUJ2ߩ⹜ᢱߩ⠻㊂߇ห⒟ᐲߦߥߞߚߣᕁ ࠊࠇࠆ㧚

߹ߣ

ᧄ⺰ᢥߢߪ㧘RFࡊ࠭ࡑCVDᴺࠍ↪ߡPPSၮ᧼

ߦᒻᚑߒߚDLC⤑ߩ․ᕈߦߟߡ⺞ᩏߒߚ㧚ᓧࠄࠇ ߚ⚿ᨐࠍએਅߦㅀߴࠆ㧚

(1)RFജߩჇടߦ㧘ᒻᚑߐࠇߚDLC⤑ߪ✺ኒൻ

ߒߡߚ㧚ߚߛ㧘ജߩჇടߣߣ߽ߦ⊹⤑ߩౝㇱᔕജ ߇Ⴧᄢߔࠆߚ㧘⊹⤑㕙ߦഀࠇ߇⊒↢ߔࠆߎߣ߇ࠊ ߆ߞߚ㧚

(2)RFജߩჇടߦ㧘DLC⤑ߩ⎬ߐ߇Ⴧᄢߒߚ㧚

(3)ࠬࠢ࠶࠴⹜㛎ߩ⚿ᨐ㧘RF300WߢᒻᚑߒߚDLC⤑ ߇ᦨ߽ኒ⌕ᕈ߇㜞߆ߞߚ㧚ߚߛ㧘ઃ⌕ജߦߟߡߪ

RF400WߢᒻᚑߒߚDLC⤑ߩᣇ߇㜞ߣផ᷹ߐࠇߚ㧚

(4)⦟ᅢߥᡂ․ᕈࠍᓧࠆߚߦߪ㧘ᡂ⋧ᚻ᧚ߩᡂ 㕙ߦ⒖⌕⤑ߩᒻᚑ߇㊀ⷐߢࠆߎߣ߇␜ໂߐࠇߚ㧚 (5) RF100W㧘200WߢᒻᚑߒߚDLC⤑ߩᲧ⠻㊂ߪ㧘 ࡏ࡞ߦ㊄ዻ᧚ᢱࠍ↪ࠆߣᄢ߈߆ߞߚ߇㧘ࡒ࠶

ࠢ᧚ᢱࠍ↪ࠆߣዊߐߊߥߞߚ㧚৻ᣇRF300W㧘400W ߢᒻᚑߒߚDLC⤑ߪ㧘ࡏ࡞᧚ᢱߦࠃࠄߕ㧘Ყ⠻㊂ ߪዊߐߎߣ߇ࠊ߆ߞߚ㧚

ᧄ⎇ⓥߪ㧘ᄹ⦟⋵Ꮏᬺᛛⴚࡦ࠲ ਃᧁ㕏ᶈ✚

⎇ⓥຬ㧘⿷┙⨃ኡਥછ⎇ⓥຬߩᄙᄢߥࠆߏදജߏᜰ ዉࠍฃߌߡㆀⴕߐࠇߚ㧚ߎߎߦ⸥ߒߡ㧘ᷓ↟ߩ⻢ᗧࠍ

ߒ߹ߔ㧚

ෳ⠨ᢥ₂

1㧕 ਛ᧲ቁᶈ㧘ᯏ᪾⸳⸘㧘̌DLCࠦ࠹ࠖࡦࠣߦࠃࠆήẢṖ

᠁േߣㇱຠߩήẢṖಾ̍㧘48㧘23-27 (2004).

2㧕 ⨹’ノᄦ㧘̌ᣂߒ㧼㧼㧿♽ߒࠀ߁േ᧚ᢱߩ․ᓽߣᔕ↪̍㧘

࠻ࠗࡏࡠࠫࠬ࠻㧘34㧘642-647 (1989).

3㧕 ਃቛᱜੑ㇢㧘ᢧ⮮༜჻㧘ᷰㇱୃ৻㧘ᨋᩕ৻㧘ਛਣ㓉㧘̌ࡑ

ࠣࡀ࠻ࡠࡦࠬࡄ࠶࠲ࡦࠣߢᒻᚑߒߚ࠳ࠗࡗࡕࡦ࠼

ࠗࠢࠞࡏࡦ㧔DLC㧕⤑ߦࠃࠆ⠴ᾲᕈ㜞ಽሶ᧚ᢱߩᡂ̍㧘

㕙ᛛⴚ㧘52㧘878-882 (2001).

4㧕 ⿒ℂቁ৻㇢㧘̌DLC ⤑ߩኒ⌕ᕈะᛛⴚ̍㧘࠻ࠗࡏࡠ

ࠫࠬ࠻㧘47㧘809-814 (2002).

5㧕 A. C. Ferrari and J. Robertson, “Interpretation of Raman

spectra of disordered and amorphous carbon”, Physical Review B, 61, 14095-14107 (2000).

6㧕 ᄢ┻ዏ⊓㧘㜞㑆ᐽਯ㧘ጟ↰ᜏ㧘ട⮮ౖ̌ὶ㔚ᕈ㜞ಽ ሶࡈࠖ࡞ࡓ߳ߩࠕࡕ࡞ࡈࠔࠬ⚛⤑ߩวᚑ߮ߘߩ ශࡊࡠࠬ߳ߩㆡ↪̍㧘ᣣᧄᯏ᪾ቇળ⺰ᢥ㓸C✬㧘67㧘 547-552 (2001).

7㧕 I. R. Lewis and H. G.M. Edwards, Handbook of Raman Spectroscopy: From the Research Laboratory to the Process Line, (Marcel Dekker, New York, 2001), p.989.

8㧕 Y. Ohkawara, S. Ohshiio, T. Suzuki, H. Ito, K. Yatsui and H.

Saitoh : “Quantitative Analysis of Hydrogen in Amorphous Films of Hydrogenated Carbon Nitride”, Jpn. J. Appl. Phys., 40, 7007-7012 (2001).