D&T

ira nsia:n o_n

This article is translated in revised form from

Monographs

of

theDes4itn

Awtoiatnior

Working Grouip oftheInform,ation ProcessingSocietv ofJapan, Vol. 19,No.3, Nov. 1983. and isreprinted withpermission. © 1983 IPS.1

Design for Testability

for Complete Test

Coverage

Very large scale circuits present great obstacles to complete

testing. A pattern generation algorithm offers a direct approach

to the problem.

Akira Motohara and Hideo Fujiwara, Osaka University

T he

problem

ofreliability

isgain- make

itdifficult

toachieveahigh

rateT

ing increasing importance with of test coverage.the rapid advance of semiconductor

Designing

fortestability

has been technology toward very large scale in- offered as asolution of

thisproblem

tegration of logic circuits. The very (see Williams and Parkeri).

Methods large scale of the circuits, however, to reduce thecomplexity

oftesting

for makes test pattern generationextreme-sequential circuits

to thelevel for

com-ly difficult,

and when test patterns can-binational circuits

havebeen proposed

not be obtained within the allowed andachieved.24 However, for

com- computation time, abortedfaults

binationalcircuits of large scale,

it is stillextremely

difficultto achieve 100 percent test coverage.summary Among the

mostpromising DFT

Some design-for-testability techniques, such as level-sensitive scan methods are those aimed at complete design, scan path, and scan/set, reduce test pattern generation of sequen- test coverage through the addition ofa tial circuits to that ofcombinational circuits by enhancing the controllabili- few hardware elements to thecircuit. ty and/or observability of all the memory elements. However, even for

com-

This redundant hardware is called test binational circuits, 100 percent test coverage of large-scale circuits ispoints. 5'6

The test point strategies we generally very difficult to achieve. This article presents DFT methods are considering here fall into four cate- aimedatachievingtotalcoverage. Two methods arecompared: One,basedgories-

on testability analysis, involves the addition of test points to improve

g1

Iert

AND OR t testability beforetest pattemgeneration.The other method employs a test(1) Inse N,O gates.

pattem generation algorithm(the FAN algorithm). Results show that 100 (2) Change NOT gates to NOR, percent coveragewithintheallowed limits is difficult with the former ap- NAND, gates.

proach. The latter, however,enables us to generate a test pattern for any

(3)

Addprimary input points

for detectable fault within the allowed time limits, and 100 percent test control.coverage is possible. (4) Add primary output points

for

observation.

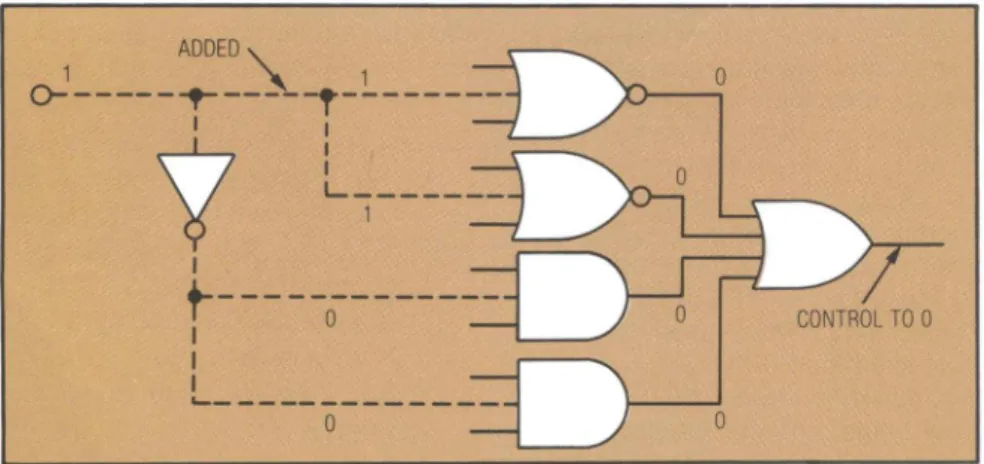

These strategies are illustrated in

Figuire

1.When two or more of the control test

points (Figure

1, a-c)aretobeused

at thesametime, thev'are merged into oneprimarv input to reduce the num- ber of additional input points (Figure 2).Moreover, ifscan-pathtechnliqlS,

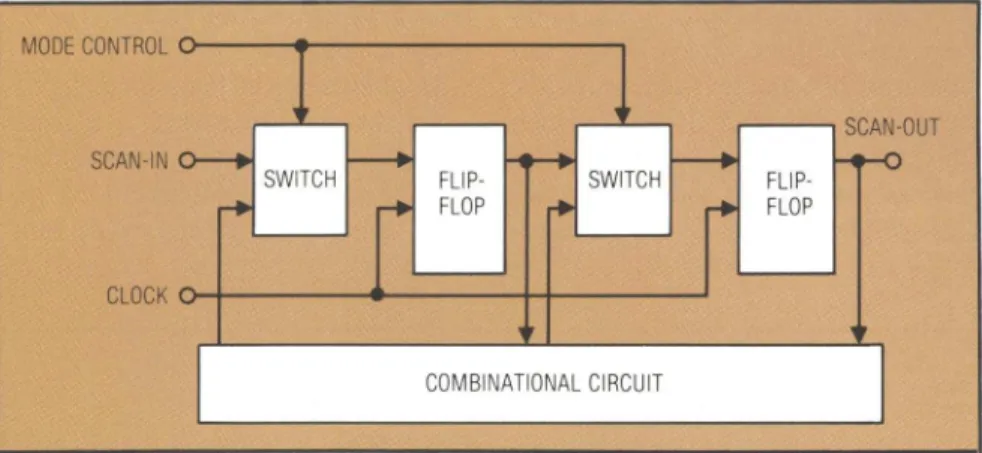

asshowniinFigure3,areused,one test

point wvillthen correspond toone flip- flop,and the increase in thenuimberof external points can be avoided.

We have investigated two methods ofalteringcircuitstofacilitatetestabil- itythroughthe addition oftest points.

Thefirst method is basedontestabilitv analvsis and involves the addition of test points to improve testability be- fore a test pattern is generated. Ob- tained results show that 100 percent test coverage within the allowed time limits is difficult to achieve with this method. The second method

emiploys

a test pattern generationalgorithm,

enablinig

us to generate a test pattern for any detectable fault wvithin the allowed time limits, andmaking

100 percenttest coveragepossible.Wepro-grammed the twomethods, and after

evaluating

some circuits with several thousandgates.,

vewereabletoobtain very favorable results wvith the second method. In thisarticle wveexamnineand compare these methods.Circuits considered here are com-

binational circuitsconsisting ofAND, OR, NOT, NAND, and NOR ele- ments, and faults are assumed to be Figure 1.Typesof test

points.sigetukaful.

DFT

through

testability analysis

To increase the effectiveness oftest pattern generation, testability mea-

sures, which express the ease or dif- ficulty of testing, are used in two al- gorithms: Podem7 and Fan,8 short forpath-oriented decision-makingand fanout-oriented test generation algo- rithm, respectively.

Herewedraw attentiontothe mea- surement of testability, and we de- scribe methods ofdesignmodification that facilitate testing through the im- provement oftestability. The overall

Figure2. Additionof test

points,

flow ofthese DFTmethodsis shown inFigure 4. Although theentire process could be automated, we have imple- mentedthesystem ininteractive form to improve efficiency by enabling the designer to input the choice ofsignal

lines needing improvement and the SWTC

FLOP

SWITCH FLIP-decision as to whether the desired degree of testability has been achieved. Testability analysis. Various mea-

sureshavebeen proposedasmeasures COMBINATIONALCIRCUIT

of testability.9-1 Here we use Gold- stein's measures,9 which express the

costs of controlling and observing. Figure3. Scan path method. Thus, to maximize testability, these

costs must be minimized. Goldstein proposed six measures in all, threeof whichapplytocombinationalcirciiits:

* [CC' (L)] The smallest number TsaiiyAayi

of signal lines which must have their logical values set in orderto

Coc fSga ie

setthe logical valueof signal lineL Choiceof Signal Lines for to 1; called signal line L's "I"

controllabilitycost.

* [CCO (L)] Defined in the same lec ionofTest Point

way as [CC' (L)]; called signal InsertionLocation

line L's "O"controllabilitycost.

* [CO (L )IThe smallest numberof nserionofTest Points

signal lines whichmust havetheir logical valuessetin orderto prop-

agatethe valueofsignal line L to Hasdesired

testabty

primaryoutput;called the observ- beenachieved?

abilitycost of signal lineL. Each of these valuescan be found for any given circuit through simple cal-E_D culations.

Selectionofsignallinesneedingim-

Figure

4. Work sequence in testability analysisDFr

method. provement. At this point the designercan see from the system the greatest controllability and observability cost values. Then hedecideswhether to im- prove thecontrollabilityortheobserv- ability and sets the threshold values. Values exceeding threshold valuesare then improved, starting from those nearestthe

primary input signal

line.Test point insertion locationsearch. Insertingtestpointsasshownin Figure I, a-c, markedlyimprovesthecontrol- lability for thesignal lines ontheout-

put side of the insertion point, leaving the input side

unchanged.

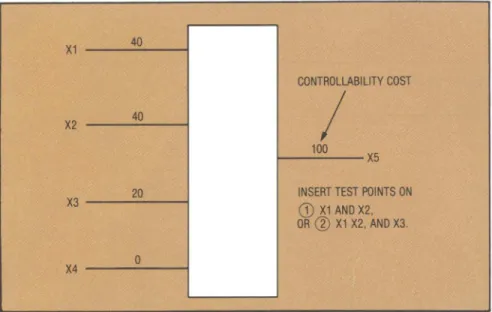

Accord- ingly, test points are inserted severalgates to the input side of signal lines Figure 5. Test point insertion location search.

with high controllability costs. Simi- duce here the method that was effec- neously high controllability cost. In larly, to improve observability, test tivein actual tests. the former case, it is best to insert atest pointsareinsertedseveralgatestothe Lookingatsignal line with highcon- point a bit further toward the input output sideofthesignallines withhigh trollability cost, we find two situa- side.Inthe latter case, insertionof the observability costs. The exact place- tions. Inthe first, oneofseveralinput test point is best on thesignal lineit- mentof test points is an extremely dif- lines dominates the others. In the sec- self. Space does not permit us to go ficultproblem, however, andweintro- ond, several input lines have simulta- into the standards used in deciding whetherwe arefaced with the firstor second situation, butwehave found it

generally

difficult to determine the mostsuitable standard.When asignal line has high control- lability cost, we find that either the observabilitycost drops

rapidly,

orit does not. With arapid drop,

we as-sume aproblemin

controllability,

andwe then search for aproper

point

of test-point insertion to lowerthe con- trollability cost (see Figure 5). Iftheobservability

costdoesnotdrop rapid-

ly,the next step is to analyze output. If no sudden drop in observability cost canbeseenallthe waythroughtothe primaryoutput,thenatestpoint

is in- sertedonthe original signalline a few gates towardthe outputside,asinFig-ure Id. Insertion so that the observ-

Figure 6. Test point insertion. ability costisonehalf of that for the

original signal linewasthemosteffec- tive.

Test point insertion methods. Fig-

ure6 shows one example ofan inser-

START

s_tion

location. The numbers appearing above each line express the control- labilitycosts. Inthisexample, thereis __ Ptomultiple inp gateGno

need to inserttest pointson inputinputside ofsignalline L lines Xltrollability cost on linethrough X4toX5.lowerInsertion ofthecon- twotestpoints,oneoneach of the lines Xl and X2 with poor controllability,

Can the method in or three test points on lines

Xl,

X2,igurelcbeapplied and X3, would be sufficient. This

Insert

testpoint

would spare us the problem of theasinFigurelc standardstobe

applied

wheninserting

Is thereanysingle _ _thetest point ontheinput line.

input gate onP? _ _ For the test point, a gate could be

added as shown in Figure la. How- ever, the addition of a gate would cause delay in a circuit designed for Inserttestpoint Insert test point high-speed operation, requiring a

asin Figurela asinFigurelb

redesign

ofthecircuit

withthe new test point. It is preferable, if possible, to use oneof the methods shown inFig-r END ure 1, b andc. Whenaddinga gate to

signal

lineL,wefollowthe flow chart in Figure 7 to determine whetherFigure 7. Selection of test point types. method lb orIccan be used.

Experimental results. After pro- all detectable faults. This method pays

fault;

when a fault isaborted,

it is gramming the design method de-special

attention toaborted faults oc- called at-difficult-to-test-for fault.

scribed above, we applied it to some

curring

after the test pattern genera- When noparticular

number ofback- circuits of several thousand gates and tionalgorithm

isapplied,

and it in- tracks isspecified,

tmaybe omitted. surveyed how the test coverage volves thesubsequent placement

of From theperspective

oftestpattern changed with the insertion of test testpoints

tomakesuch faults easiertogeneration,

aborted faults can bepoints. The computer used for our test. divided into threetypes:

calculationswasthe

large

computerat Types of aborted faults. With a test Fault type 1. An aborted fault Osaka University, an NEC System pattern generation algorithm that caused by difficulty in producing a 1000 (computation speed: 15 MIPS). sendsasignal whose value varies with faultysignal.

We used Fortran for programming, the existence or absence of a fault Fault type 2. A fault for which and for the test pattern generation (called a "faulty signal") along a faulty signal production is easy, but algorithm, we used the FAN algo- signal line on which a fault is inserted propagationof the

faulty signal

tothe rithm.8 Aborted faultswerethe faults (called a "faulty line"), we try prop- nextgate

isdifficult

ythat remained undetected after more agating a faulty signal from the faulty

Faun

t type 3.Afault

for which ob- thanThe100characteristics of thebacktrackoperations.circuits line to a primary output. When westart a backtrack cycle of a specificservation primary output

of theis faulty signal

difficult,even

atbeforedesigning fortestability arede- number(say100

times)

ofbacktracks,

though both the production and prop- scribed in Table 1. Test coveragewas t, the test pattern generation is agation of the faulty signal for more definedasfollows: aborted, indicating an aborted fault. than one gate were accomplished Testcomprehensiveness Wedifficultcanassumeto testfor.thatBelow,anabortedafault thatfaultis withoutdifficulty.

Number of detectedfaults ___ isnot

aborted-i.e.,

that doesnotap- Wecandetermine into whichof these Numberof detected faults + abortedfaults pear after alimited number of back-categories

the fault fallsby running

atracks,

t-is called a t-easily tested testpatterngeneration algorithm. Our findings are shownin thegraph inFigure8. Althoughtherearecases, as

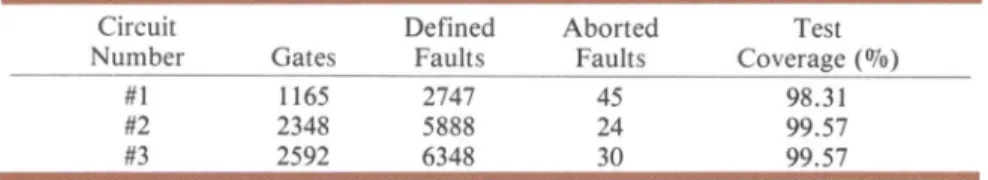

shownby circuit 3,where the insertion Table

1.

oftest points causes a clear drop in Characteristics of circuits before designing for testability. abortedfaults,therearealso cases,as

with circuit 2, where the addition of Circuit Defined Aborted Test

testpointsmakes thetestingmoredif- Number Gates Faults Faults

Coverage (%)

ficult. #1 1165 2747 45 98.31

Takingthese resultsasevidence,it is #2 2348 5888 24 99.57

clearthat themeasuresoftestabilitydo #3 2592 6348 30 99.57

notalways reflect theease or

difficulty

oftesting accurately.Also, although

the insertion oftestpointsclearly

im- proved testability, itwouldbeimpos- sibletosay that in allcasesthecircuithad been designed fortestability. \

DFT through test pattemr

generation algorithms

Asshown above, it is difficulttoob- tain complete test coverage with methodsbasedon

testability analysis.

In fact, for the number oftestpoints

added, thetestcoverage didnoteffec- tivelyimprove. Here,therefore,we ex- pand upon a method that ensures generation of test patterns for all detectable faults within the allowed computation time-in otherwords,

a method ofaddingtestpoints thatwillresult in 100 percent test coverage for Figure8.Experimentalresults oftestability analysismethod.

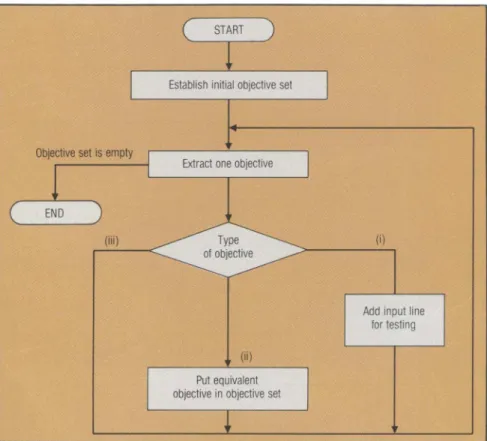

Insertion oftestpoints. Theoverall

START

~~~~~~~flow

is shown in Figure 9. The testpoints are of two types, showvn in

Generatepatterntest ~Figure 1, c and d. The following dis-

l 11|1 - for all faults _ cussion covers the methods of test

point insertion based on the type of aborted fault:

- allSlUck-PlaceCpericncesa

abortedtau

on (1)orte2 faultlist

_||LookigFault

t"ype

I. Test point insertionfollowstheflow chart inFigure 10,in- suringthat a

faulty

signa can e pro-selectt abortedsfault listanput duced without backtracking.

_tgenerat

clesttoprmatrnpt

_When we are tryingto assigna cer- tain value to a certain signal line, thevalueand the signal line are together ncalled an "objective." Several objec-

fault selected

tives held simultaneously are called a

"1setof

objectives."

Whensignal

linelexperiences a stuck-at fault at either0

nsert Insert or I in atype I fault, the initial objec-

s ing,

inttive

Tessis(0, L) or (I, L).st tLooking at the "type of

objective"

frame in Figure 10, wecan seethat for type(i),wecan meettheobjective byin- Select all faultstron serting a test

point

ofthe

type seen inaborted fault list and

Figure

Ic. For type (ii), the objective type 3 fault list and~~cannot

bemet. Fortype(iii), thesignal

generatetestpattern. line isaprimary

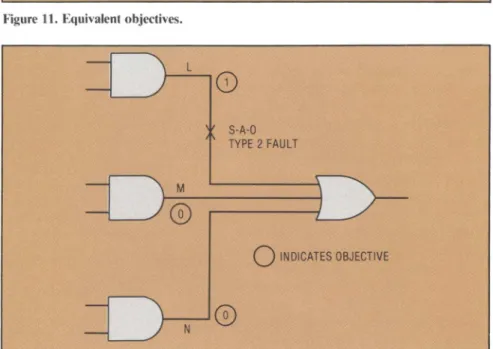

input,andnotestpoint is needed. With type(ii),weneedtoseeFigure9.Overallflow oftestpoint insertion, whattype ofvalueon theinput would enable the objective to be achieved. That value would be called the START

~~~~~~~~~~equivalent

objective" (Figure I1).After several test points have been inserted in accordance with the flow Etblishinitialobjectivese chartinFigure 10, theobjectivesetwill become empty andtheinsertion ofthe test points will be complete. For test-

ing, these input lines will become one

Extract one objective

~~~test

point according tothe circuitcon-struction in Figure 2.

Fauilt tYpe

2. Testpointinsertion for a type 2 fault is also carried out ac-.YV.

~~~~~~~~~cording

toFigure 10. However,thein-of objective

~~~~~~~itial

objectivesetis determined inadif- ferent manner from that for a type I fault.When,asinFigure

12,wehavea Addinputline stuck-at 0 fault onsignallineL,the in-testingfor itialobjective set is

~(I,L

),(0,M),

(0,N)Ptequivalent

Fut 'Ts on neto oobtectiveinobjectiveset

Faity~pe3.

Ts oitisrto oa type 3 fault is carried out only after testpointinsertion has beencompleted for fault types 1 and 2. Thetest

point

Figure10. Testpointinsertion fortypeI and type2 faults. usedisshowninFigure Id,andthefol-lowing procedures are followed to minimize the numberoftest pointsto be inserted:

First, for each

faulIt,

makea search forpossible locations that ensure that test point insertion facilitates detec- tion. Once located, a faulty signal should be produced and propagationattempted, inthesame manner as for Figure 11.Equivalent objectives.

classifying

aborted faults.Next,choose the smallestnimber of test point insertion locations that will enable all faults to be detected.

If we are to eliminate all aborted faultsby the above method, any fault occurring in the newlv added test points must be easily testable. Fol- lowingthe flow chart in Figure9, we can avoid a difficult-to-detect fault in the test points in the manner shown briefly belowv:

First, for the test point insertion shown in

Figuire

Ic, used with faulit types I and 2, consider the exarnple shownin Figure 13. Astuck-at0fault at test pointXisequivalentto astuck-at0 faultat Yand is thus easyto test

Figure

12. Initial objective fortype

2fault. for. A stuck-at 1 fauilt at X becomesredundant ifthestuck-at0faultat Yis redundant, andbecomes testableifthe stuck-at 0faultat Yis testable, because it can be tested by the same test pattern with X = 0. Thus, the stuck-at I fault at X can be seen as the equivalent of the stuck-at0faultat Y. Accordingly, the number of difficult-to-test-for

faults does not increase. Figure 13. Exampleoftestpointsfor faulttypesI and 2. Second,to usethe methodshown in

Figure Id for type 3 faults, consider the example shownin Figure 14. This type of test point insertion is carried outaftertypes I and 2 havebeen elim- inatedfrom the circuit. Accordingly, it iseasy to set signalline Yat either 0 or 1, making it easy to test signal line X.

Figure 14. Example of test points forfaulttype 3. Fxperimental results.The resultswe

obtainedfrom programming theDFT Table 2.

method incorporating a test pattern Results of design for testability withtest pattern generation algorithm. generation algorithm are shown in

Table 2. The computer, thelanguage, Circuit Computation Test

and theapplied circuits we used were Number Added Input AddedOutput Time(sec.) Coverage (o)

all the same as those we used for the #1 3 8 13.7 100.0

testability analysis method. As shown #2 1 6 11.3 100.0

inTable2,withthetestpatterngenera- #3 4 4 14.5 100.0

tion algorithm, circuits of from 1000 References 6. W.Coyand A.Vogel,"InsertingTest

to3000gateswere100percenttestable Points forSimpleTest Generation,"

with the addition of only about 10 test Proc. Fourth Intl Conf. Fault-

1. T. W. Williams and K. P. Parker, Tolerant

Systems

and Diagnostics, points. Theratiobetween the number "Design for Testability-a Survey," 1981, pp.180-186.

of the first aborted faults and the Proc. IEEE,Vol.71, No.1,Jan. 1983, 7. P. Goel, "An Implicit Enumeration number oftest points was3.4to4.1. pp.98-112. Algorithm to GenerateTests for

Com-

Compared with the resultsof thetest- . binational Logic Circuits," IEEE ability analysis method, insertion of 2. M- J. Wilhams and J. B. Angell, Trans. Computers, Vol.C-30,No.3, testpointswashighly effective.Integrated Circuits via Test

Point and Mar. 1981,pp. 215-222.Computation time. To lessen the Additional Logic," IEEE Trans. 8. H. Fujiwaraand T. Shimono, "On number oftestpoints,whenevera test Computers, Vol. C-22, No. 1, Jan. the Acceleration of Test Generation point ofthetype shown inFigure lc 1973,pp. 46 60. Algorithms," Proc. 13thFault Tolerant Computing, JuneInt'lConf. was inserted, test pattern generation 3. E. B. Eichelberger and T.

W.

1983, pp. 98-105; also IEEE Trans. wasconducted for all aborted faults. Williams, "A Logic Design Structure Computers, Vol. C-32, No. 12, Dec. Because of this, each circuit took 10-15 forLSI Testing," Proc. 14th Design 1983,pp. 1137-1144.seconds. Theprocesstookprecedence Automation Conf., June 1977, pp. 9. L. H. Goldstein, "Controllability/ over redesigning and comprised 7-30 462-468. Observability AnalysisofDigitalCir- percent of the time required for test 4 S F N cuits," IEEE Trans. Circuits and

patte genratin.Hweve, cosid- 4. S.Funasu, . Waatsui, ad T.

Systemzs,

Vol. CAS-26, No. 9, Sept.pattern generation. However, consid- *

Arima,

"TestGenerationSystems in

1979, pp.685-693.

ering that there isusuallynoguarantee Japan," Proc. 12th Design Automa- 10.

P. G. Kovijanic, "Testability

Analy- that test coverage will always be 100 tionSymp., June1975, pp. 114122. sis," Digest ofPapers,

1979 Test percent eveniftestpatterngeneration 5. J. P. Hayes and A. D. Friedman,Conf.,

pp.310-316.

time is extended by this amount, we "Test

Point Placement

to Simplify 11. H. Fujiwaraand H. Ozaki,"A

Newbelieve the time is a small price for FaultDetection," IEEE Trans.

Com-

Measure for Test Generation by a completetestcoverage. puters, Vol. C-23, No. 7, July 1974, Heuristic Method," IECE mono- Astotheexpenseinvolved in adding pp. 727-735. graph, EC80-38,Oct. 1980,pp. 1-8. hardware,weusedaverylow numberof test points and only those which could be realized at aminimumcost; thuswebelieve thatcostisnot agreat

problem.

A mong themethodswehave dis- cussedand mentionedhere,the methodutilizinga testpatterngenera- tion algorithm obtained the best resultsby far. We attribute thisto our useofadirect solutiontotheproblem

ofdifficult-to-test-for faults. [ AkiraMotohara is a graduate student in the HideoFujiwara has beenwith the Depart- Department of Electronic Engineering, ment of Electronic Engineering of Osaka Faculty ofEngineering, at Osaka Universi- University since 1974. In 1981 he was a ty. Hisresearch interests include test pat- visting assistant professor at theUniversity terngeneration, design for testability, logic ofWaterloo, and,in1984, avisitingassoci- simulation, and faultsimulation. ate professor at McGill University, Can- Hereceived the BE degree in electronic ada. His research interestsincludeswitch- engineering from Osaka University in1983. ing theory, design for testability, test He is amember ofthe Institute of Electron- patterngeneration, faultsimulation, built- ics and Communication Engineers of inself-test, and fault-tolerant systems.

ACknowledgments

Japan. Fujiwara received the BE, ME, and PhDWe wish to thank Hiroshi Ozaki, pro- degrees in electronic engineering from

fessor emeritus at Osaka University, for his OsakaUniversityin 1969, 1971, and 1974

support andencouragement of thiswork. respectively. Hewasmember of the Tech-

We also thank the members of the sixth nical ProgramCommittee ofthe 1982 In-

chair of the Department of Electronic ternational Symposiumon Fault-Tolerant

Engineering, Osaka Univeristy, for their Computing. He received an Institute of

valuable discussions. Special thanks to Electronics and CommunicationEngineers

Kenjiro Sasaoka (presently with MITI) for Theauthors' address is Department of Young Engineer Award in 1977. He isa the testabilityprogramming aswellas the Electronic Engineering, Faculty of Engi- senior memberoftheIEEE, a member of results of the test pattern generationexperi- neering, Osaka University, 2-1 Yamada- the IECEof Japan, and a member of the ment. Oka, SuitaCity,Osaka 565, Japan. InformationProcessingSocietyofJapan.